The Science Behind Corrosion-Resistant PAC Clad Panels

Advanced Material Composition

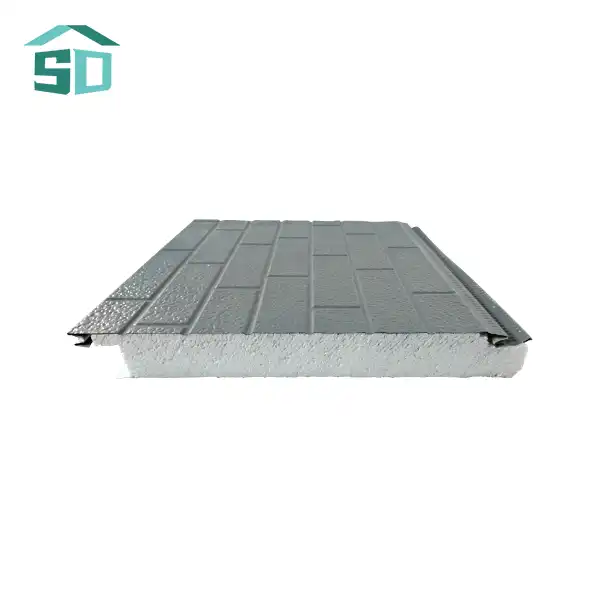

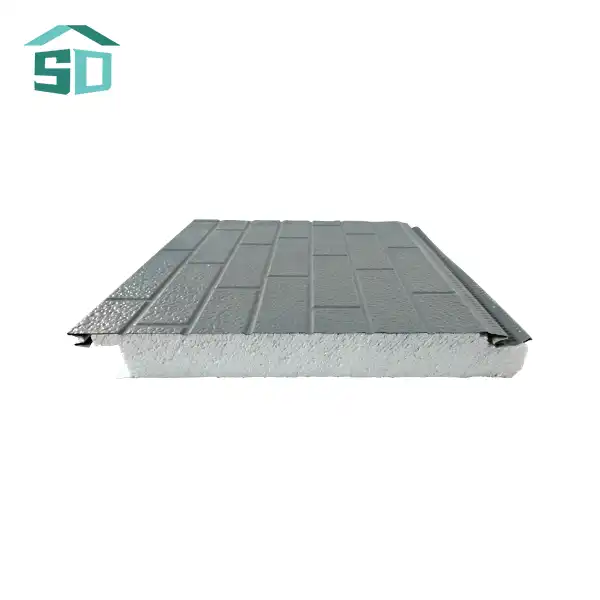

PAC clad wall panels are expertly manufactured using advanced, high-performance materials designed to deliver long-term protection against corrosion and environmental damage. At the core of each panel lies a rigid, high-density polyisocyanurate (PIR) foam, prized for its excellent thermal insulation, low moisture absorption, and fire-resistant characteristics. This insulating core is securely bonded between two durable metal facings, which provide strength and structural stability. To enhance durability, these metal surfaces are coated with specialized protective finishes that create a resilient barrier against corrosive agents such as moisture, chemicals, and airborne pollutants commonly found in demanding environments.

These coatings frequently incorporate high-performance fluoropolymer-based finishes, most notably PVDF (polyvinylidene fluoride), which are widely recognized for their exceptional durability in challenging environments. PVDF offers outstanding resistance to ultraviolet (UV) radiation, significantly reducing the risk of fading, chalking, or surface degradation over time. In addition, it provides excellent protection against chemical exposure and prevents moisture infiltration, both of which are primary contributors to corrosion. By combining these advanced protective finishes with robust structural components, the panel system maintains its visual appeal, structural strength, and overall performance, even when exposed to harsh weather and industrial conditions.

Innovative Manufacturing Processes

The manufacturing of PAC clad wall panels involves a highly controlled, precision-engineered process designed to maximize corrosion resistance and ensure long-term performance. It begins with the meticulous selection of raw materials, such as high-grade galvanized steel or aluminum, chosen for their mechanical strength, durability, and inherent resistance to environmental degradation. Each batch of metal undergoes stringent quality control procedures, including chemical composition analysis and surface integrity testing, to confirm its suitability for high-performance cladding applications.

Once verified, the metal facings are prepared for assembly through surface treatments that promote optimal adhesion. They are then bonded to a rigid polyisocyanurate (PIR) insulation core using advanced, industrial-grade adhesives that create a continuous, uniform seal. This seamless integration helps prevent moisture ingress and eliminates potential weak points where corrosion could initiate. After lamination, the composite panels are subjected to a multi-step surface conditioning process—typically including cleaning, passivation, and priming—to further enhance corrosion resistance. Finally, a high-performance protective coating, such as a fluoropolymer finish, is applied to ensure long-lasting durability, UV stability, and aesthetic appeal in even the most demanding environments.

Benefits of Corrosion-Free PAC Clad Panels

Extended Lifespan and Reduced Maintenance

One of the primary advantages of utilizing corrosion-free PAC clad panels is their proven ability to significantly prolong the service life of building exteriors. While traditional cladding materials may suffer from rust, fading, and surface deterioration due to exposure to moisture, pollution, and UV radiation, PAC panels are engineered to withstand these conditions without compromising performance. Their superior durability ensures that the exterior facade remains structurally sound and visually appealing for decades, resulting in fewer maintenance interventions and substantially lower long-term ownership costs for building developers and facility managers.

The corrosion-resistant properties of PAC clad wall panels also contribute to their exceptionally low maintenance requirements. Thanks to their high-performance protective coatings, the panels resist dirt accumulation, staining, and surface degradation. As a result, routine upkeep is limited to simple cleaning using water and mild detergents, eliminating the need for abrasive materials or specialized maintenance procedures. Unlike conventional cladding systems, which may require periodic repainting, refinishing, or even replacement due to corrosion or weathering, PAC panels maintain their appearance and functionality with minimal effort, making them a practical and cost-effective solution for long-term building maintenance.

Versatility in Design and Application

Corrosion-free PAC clad panels offer architects and designers a wide range of creative possibilities. These panels are available in various colors, textures, and finishes, allowing for customization to suit any architectural style or aesthetic preference. The panels can be fabricated in different shapes and sizes, enabling the creation of unique façade designs that stand out while providing superior protection against corrosion.

The versatility of PAC clad panels extends to their application across diverse building types. From residential complexes and office buildings to industrial facilities and educational institutions, these panels provide a durable and attractive cladding solution that can withstand the specific environmental challenges of each setting.

Environmental Impact and Sustainability

Energy Efficiency and Thermal Performance

Beyond their corrosion-resistant properties,PAC clad wall panels contribute significantly to a building's energy efficiency. The insulated core of these panels provides excellent thermal performance, helping to reduce heating and cooling costs. By maintaining a stable interior temperature, PAC clad panels minimize the energy demand of HVAC systems, leading to lower carbon emissions and reduced environmental impact.

The longevity of corrosion-free panels also plays a role in sustainability. By reducing the need for frequent replacements or repairs, these panels help conserve resources and minimize waste associated with building maintenance and renovations.

Recyclability and End-of-Life Considerations

Many manufacturers of PAC clad panels are committed to sustainability throughout the product lifecycle. The materials used in these panels are often recyclable, and some companies offer take-back programs to ensure proper recycling or repurposing of panels at the end of their service life. This focus on recyclability aligns with green building initiatives and helps reduce the environmental footprint of construction projects.

Furthermore, the durability of corrosion-free panels means that they contribute to the overall longevity of buildings. This extended lifespan reduces the need for new construction and the associated environmental impacts of producing and transporting building materials.

Conclusion

Corrosion-freePAC clad wall panels represent a significant advancement in building envelope technology. Their ability to provide long-lasting protection against environmental factors while offering aesthetic versatility makes them an ideal choice for modern construction projects. By investing in these innovative panels, building owners can ensure the longevity of their structures, reduce maintenance costs, and contribute to more sustainable building practices.

For those seeking to enhance their building's durability and appearance with corrosion-free PAC clad panels, Weifang Sandong Building Materials Co., Ltd. offers a comprehensive range of high-quality cladding solutions. To learn more about our products and how they can benefit your next project, please contact us at info@sdqsc.com.