- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Comparing PU Sandwich Panels to Other Insulation Options

When it comes to building construction and renovation, choosing the right insulation material is crucial for energy efficiency, comfort, and cost-effectiveness. Among the myriad options available, PU sandwich panels have emerged as a popular choice for their exceptional performance and versatility. In this comprehensive guide, we'll explore how PU sandwich panels stack up against other insulation options, helping you make an informed decision for your next project.

Understanding PU Sandwich Panels: A Game-Changer in Insulation

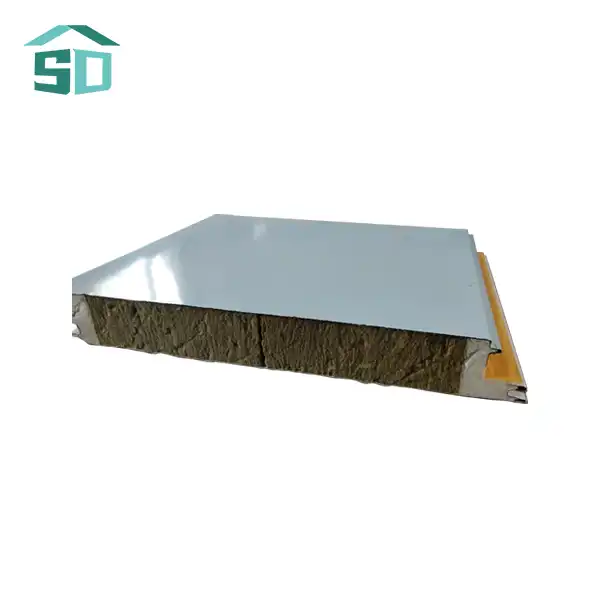

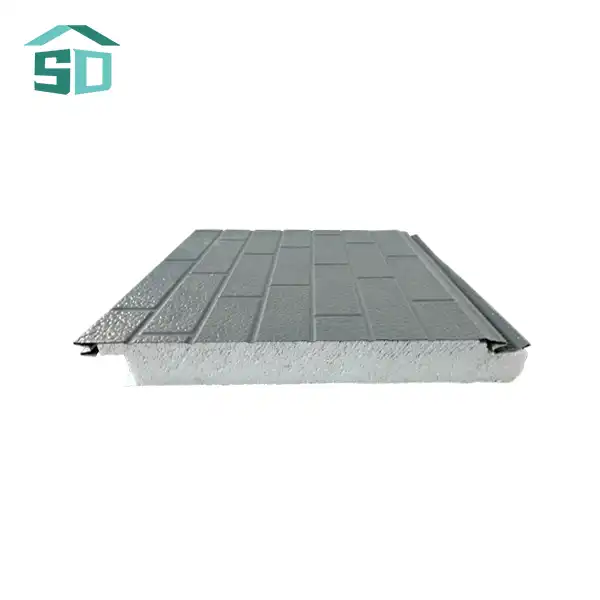

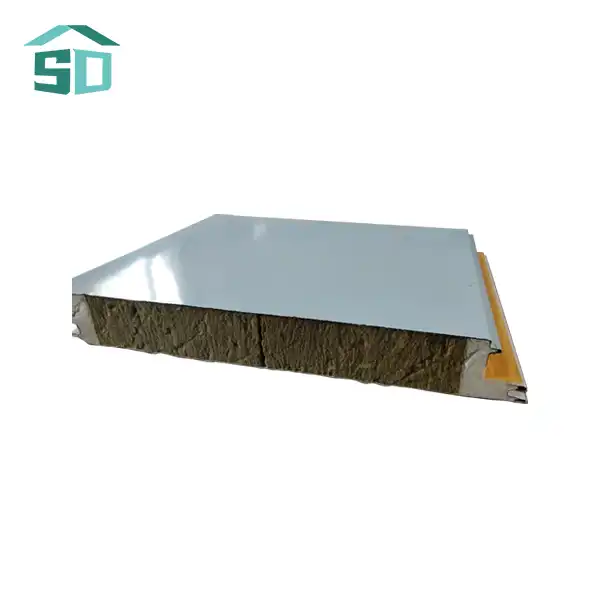

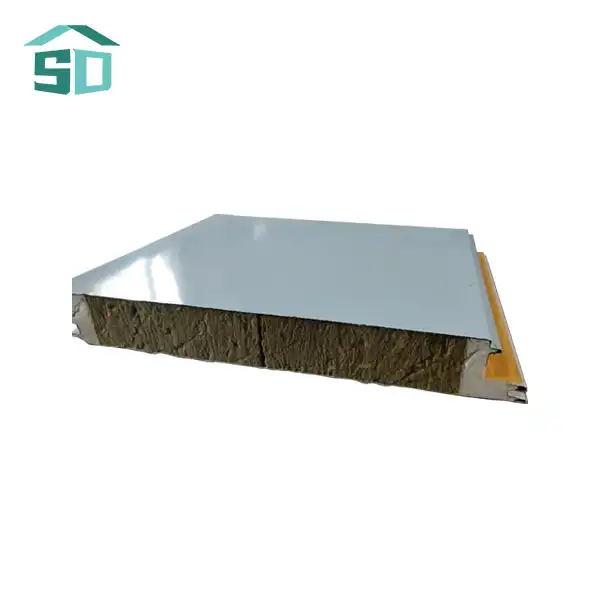

PU sandwich panels, also known as polyurethane sandwich panels, are composite materials consisting of two metal facings with a polyurethane foam core. This innovative construction offers a unique combination of strength, lightweight properties, and superior insulation capabilities. The polyurethane core is the secret behind the panel's remarkable insulation properties. With its closed-cell structure, PU foam effectively traps air, creating a formidable barrier against heat transfer. This results in excellent thermal performance, helping maintain consistent indoor temperatures while reducing energy consumption.

Weifang Sandong Building Materials Co., Ltd., a global provider of exterior cladding and facade solutions, has been at the forefront of PU sandwich panel technology. Their state-of-the-art production lines and rigorous quality control systems ensure that each panel meets the highest standards of performance and durability. The versatility of PU sandwich panels is truly remarkable. They find applications in a wide array of construction projects, including residential complexes, office buildings, villas, and even historic building renovations. Architects and builders often opt for these panels due to their superior performance and aesthetic appeal, making them a first choice for modern construction needs.

PU Sandwich Panels vs. Traditional Insulation Materials

To truly appreciate the benefits of PU sandwich panels, it's essential to compare them with other common insulation materials. Let's examine how they measure up against some popular alternatives:

Fiberglass Insulation

Fiberglass has long been a staple in the construction industry, known for its affordability and ease of installation. However, when compared to PU sandwich panels, fiberglass falls short in several key areas:

- Thermal Performance: PU sandwich panels offer superior R-value per inch, meaning they provide better insulation with less thickness. This can be particularly advantageous in spaces where every inch counts.

- Moisture Resistance: Unlike fiberglass, which can absorb moisture and lose its insulating properties, PU sandwich panels are inherently moisture-resistant. This helps prevent mold growth and maintains insulation effectiveness over time.

- Structural Integrity: PU sandwich panels contribute to the structural strength of a building, whereas fiberglass is non-load bearing.

- Longevity: PU sandwich panels maintain their insulating properties for decades, while fiberglass can settle and lose effectiveness over time.

Expanded Polystyrene (EPS)

EPS is another popular insulation material, often used in construction due to its lightweight nature and reasonable insulation properties. However, PU sandwich panels offer several advantages:

- Higher R-value: PU foam provides better thermal insulation per inch compared to EPS, allowing for thinner wall constructions without compromising on energy efficiency.

- Fire Resistance: PU sandwich panels can be manufactured with fire-retardant properties, offering better safety features compared to standard EPS.

- Durability: PU sandwich panels are more resistant to degradation from UV exposure and chemical reactions, ensuring longer-lasting performance.

- Versatility: The metal facings of PU sandwich panels offer greater design flexibility and can be finished in a variety of colors and textures.

Mineral Wool

Mineral wool, also known as rock wool, is praised for its fire resistance and sound insulation properties. However, PU sandwich panels hold their own in comparison:

- Weight: PU sandwich panels are significantly lighter than mineral wool, making them easier to handle and install, particularly in large-scale projects.

- Moisture Handling: While mineral wool can absorb moisture, potentially leading to reduced insulation performance, PU sandwich panels remain unaffected by moisture, maintaining their efficiency.

- Thermal Bridging: The continuous insulation provided by PU sandwich panels helps minimize thermal bridging, a common issue with mineral wool installations.

- Installation Efficiency: PU sandwich panels can be installed more quickly and with less labor, potentially reducing overall construction time and costs.

The Environmental Impact of PU Sandwich Panels

In today's eco-conscious world, the environmental impact of building materials is a critical consideration. PU sandwich panels offer several environmental benefits that set them apart from other insulation options:

Energy Efficiency

The superior insulation properties of PU sandwich panels contribute significantly to energy efficiency in buildings. By reducing the energy required for heating and cooling, these panels help decrease overall energy consumption and associated carbon emissions. This long-term energy saving can offset the initial carbon footprint of production, making products a sustainable choice for environmentally conscious builders and homeowners.

Longevity and Recyclability

PU sandwich panels are designed for durability, with a lifespan that can exceed 50 years when properly maintained. This longevity reduces the need for frequent replacements, minimizing waste and resource consumption over time. Additionally, at the end of their life cycle, many components of PU sandwich panels can be recycled or repurposed, further reducing their environmental impact.

Reduced Material Usage

The high strength-to-weight ratio of PU sandwich panels allows for thinner wall constructions without compromising on insulation or structural integrity. This can lead to a reduction in overall material usage in construction projects, contributing to resource conservation and reduced transportation emissions.

https://www.youtube.com/watch?v=2o-CTIRh6uY Cost Considerations: The Long-Term Value of PU Sandwich Panels

While the initial cost of PU sandwich panels may be higher than some traditional insulation materials, it's essential to consider the long-term value they offer:

Energy Savings

The superior insulation properties of PU sandwich panels translate to significant energy savings over the life of a building. These savings can offset the initial investment, making PU sandwich panels a cost-effective choice in the long run.

Reduced Maintenance Costs

The durability and moisture resistance of PU sandwich panels mean less frequent repairs and replacements. This can lead to substantial savings in maintenance costs over time, particularly in challenging environments or high-traffic areas.

Installation Efficiency

The ease and speed of installation associated with PU sandwich panels can result in reduced labor costs and shorter construction timelines. This efficiency can be particularly beneficial in large-scale projects or renovations where time is of the essence.

Structural Benefits

The structural contribution of PU sandwich panels can potentially reduce the need for additional support elements in certain constructions. This can lead to cost savings in materials and simplify the overall building design.

Conclusion

As we've explored throughout this article, PU sandwich panels offer a compelling combination of benefits that set them apart from other insulation options. From superior thermal performance and moisture resistance to structural integrity and environmental benefits, these innovative panels are revolutionizing the way we approach building insulation.

If you're interested in learning more about and how they can benefit your next construction project, we encourage you to reach out to the experts at Weifang Sandong Building Materials Co., Ltd. Their team of professionals can provide in-depth information about their product range and help you determine the best solution for your specific needs. Contact them today at info@sdqsc.com to explore the possibilities of PU sandwich panels for your next project.

References

1. Berardi, U., & Naldi, M. (2017). The impact of the temperature dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy and Buildings, 144, 262-275.

2. Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and Buildings, 37(1), 77-86.

3. Zhuang, X. W., Yu, L., Zhao, X. Y., & Cao, S. L. (2020). Thermal and mechanical properties of polyurethane foam/silica aerogel composite materials. Journal of Porous Materials, 27(4), 1235-1244.

4. Motuzienė, V., Rogoža, A., Lapinskienė, V., & Vilutienė, T. (2016). Construction solutions for energy efficient single-family house based on its life cycle multi-criteria analysis: a case study. Journal of Cleaner Production, 112, 532-541.

5. Schiavoni, S., D׳Alessandro, F., Bianchi, F., & Asdrubali, F. (2016). Insulation materials for the building sector: A review and comparative analysis. Renewable and Sustainable Energy Reviews, 62, 988-1011.