- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Comparing polyurethane foam insulation panels to traditional materials

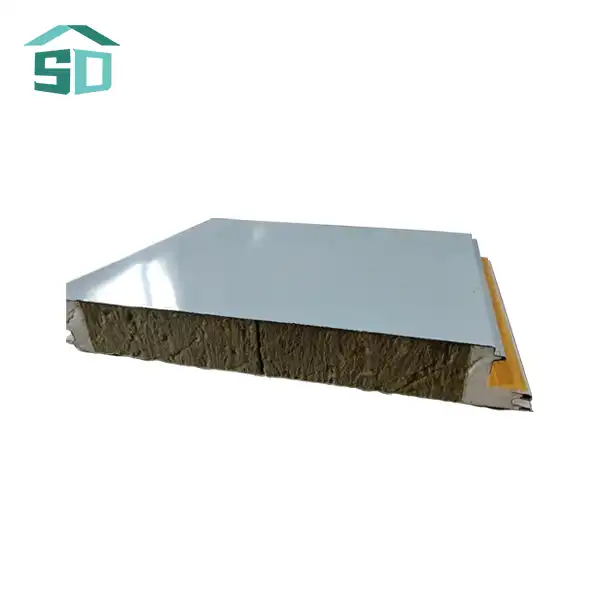

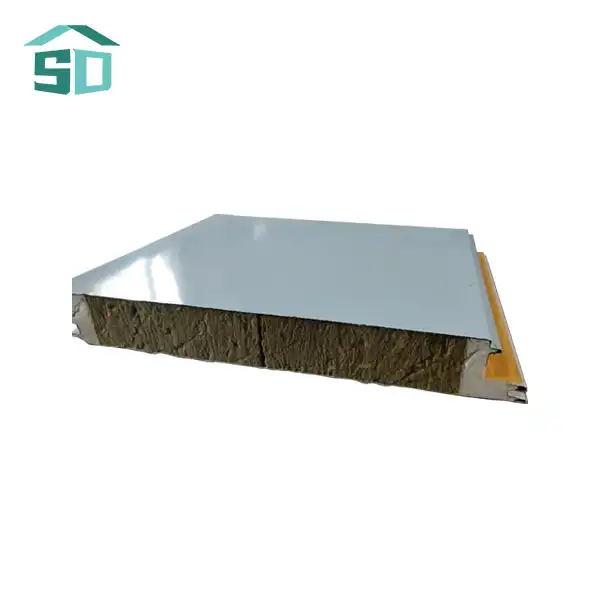

When it comes to insulation, polyurethane foam insulation panels have emerged as a game-changer in the construction industry. Compared to traditional materials like fiberglass, mineral wool, or cellulose, polyurethane foam panels offer superior thermal performance, durability, and versatility. With their exceptional insulating properties, these panels provide better energy efficiency, reduced heating and cooling costs, and improved comfort in buildings. Unlike conventional materials that may settle or degrade over time, polyurethane foam maintains its shape and effectiveness for decades, making it a cost-effective long-term solution for both new constructions and renovations.

The Science Behind Polyurethane Foam Insulation Panels

Composition and Manufacturing Process

Polyurethane foam insulation panels are the result of innovative chemical engineering. These panels are created by combining two main components: polyol and isocyanate. When these substances react, they form a rigid foam that expands and hardens, creating a dense, closed-cell structure. This unique composition is what gives polyurethane foam its exceptional insulating properties.

The manufacturing process of polyurethane foam insulation panels is highly controlled and precise. Advanced production lines ensure consistent quality and performance. Each panel undergoes rigorous testing, including checks for thickness, mechanical strength, and flame retardancy. This meticulous quality control process guarantees that every panel meets the highest standards of performance and safety.

Thermal Conductivity and R-Value

One of the most significant advantages of polyurethane foam insulation panels is their low thermal conductivity. With a thermal conductivity rating of ≤ 0.022 W/(m·K), these panels significantly outperform traditional insulation materials. This low conductivity translates to a higher R-value per inch of thickness, meaning that polyurethane foam can provide superior insulation with less material.

The high R-value of polyurethane foam insulation panels allows for thinner walls without compromising on insulation performance. This is particularly beneficial in renovation projects where space is at a premium, or in new constructions where maximizing interior space is a priority. The ability to achieve excellent insulation with thinner panels also contributes to more design flexibility for architects and builders.

Advantages of Polyurethane Foam Insulation Panels

Energy Efficiency and Cost Savings

The superior insulating properties of polyurethane foam panels translate directly into energy savings. By creating a more effective thermal barrier, these panels reduce heat transfer between the interior and exterior of a building. This results in lower heating costs in winter and reduced cooling expenses in summer. Over time, the energy savings can offset the initial investment in polyurethane foam insulation.

Moreover, the longevity of polyurethane foam insulation panels ensures that these energy-saving benefits persist for decades. Unlike some traditional materials that may settle or degrade over time, polyurethane foam maintains its shape and insulating properties, providing consistent performance throughout the life of the building.

Moisture Resistance and Air Sealing

Polyurethane foam insulation panels offer excellent moisture resistance, a crucial factor in maintaining a healthy and durable building envelope. The closed-cell structure of the foam prevents water vapor from penetrating the insulation, reducing the risk of mold growth and structural damage associated with moisture infiltration.

Additionally, these panels provide superior air sealing capabilities. When properly installed, polyurethane foam creates an airtight barrier that significantly reduces air leakage. This not only enhances the overall insulation performance but also improves indoor air quality by preventing the infiltration of outdoor pollutants and allergens.

Versatility and Ease of Installation

Polyurethane foam insulation panels are remarkably versatile, suitable for a wide range of applications. They can be used in walls, roofs, floors, and even in specialized applications like refrigerated storage or transportation. The panels are available in various thicknesses (50mm, 75mm, 100mm, 150mm) and sizes (typically 1200mm x 2400mm), allowing for customization to fit specific project requirements.

Installation of polyurethane foam insulation panels is straightforward and efficient. Their lightweight nature makes them easy to handle and maneuver, reducing labor costs and installation time. The panels can be cut to size on-site using simple tools, ensuring a precise fit even in complex architectural designs. This ease of installation makes polyurethane foam panels an attractive option for both new construction and retrofit projects.

Environmental Impact and Safety Considerations

Sustainability and Energy Balance

While the production of polyurethane foam insulation panels does involve chemical processes, the long-term environmental benefits often outweigh the initial impact. The exceptional energy efficiency provided by these panels contributes significantly to reducing a building's carbon footprint over its lifetime. In fact, studies have shown that polyurethane foam insulation can save approximately 70 times more energy throughout its lifecycle than is required for its manufacture.

Furthermore, the durability and longevity of polyurethane foam insulation panels mean less frequent replacement and less waste generated over time. As the construction industry moves towards more sustainable practices, the long-term performance of these panels aligns well with green building objectives.

Fire Safety and Regulatory Compliance

Safety is a paramount concern in construction, and polyurethane foam insulation panels address this with their excellent fire-resistant properties. These panels are typically classified as B1 fire-rated, indicating a high level of fire resistance. This classification is crucial for meeting safety standards in various types of construction projects.

The fire-resistant nature of polyurethane foam insulation panels is achieved through the incorporation of flame retardants during the manufacturing process. These additives significantly reduce the spread of flames in the event of a fire, providing crucial time for building occupants to evacuate safely.

It's important to note that while polyurethane foam insulation panels offer excellent fire resistance, proper installation and adherence to local building codes are essential for ensuring overall fire safety in any structure.

Conclusion

Polyurethane foam insulation panels represent a significant advancement in building insulation technology. Their superior thermal performance, durability, and versatility make them an excellent choice for a wide range of construction projects. While the initial cost may be higher than some traditional insulation materials, the long-term benefits in energy savings, comfort, and building longevity often justify the investment.

As the construction industry continues to evolve towards more energy-efficient and sustainable practices, polyurethane foam insulation panels are likely to play an increasingly important role. Their ability to contribute to both energy conservation and improved indoor environmental quality aligns well with modern building standards and environmental goals.

For those considering insulation options for their next construction or renovation project, polyurethane foam insulation panels deserve serious consideration. To learn more about how these innovative panels can benefit your specific project, or to request samples and technical specifications, don't hesitate to contact us at info@sdqsc.com. Our team of experts is ready to help you make an informed decision and achieve the best insulation solution for your needs.

FAQ

How long do polyurethane foam insulation panels typically last?

With proper installation and maintenance, these panels can last for over 25 years, often outlasting the building's lifespan.

Are polyurethane foam insulation panels suitable for outdoor use?

Yes, they are highly durable and weather-resistant, making them excellent for exterior applications.

Can I customize the color of the panels?

Absolutely! While white and beige are standard options, we offer customizable colors to match your design preferences.

Do you provide installation support?

Yes, we offer comprehensive technical support, including detailed installation guidelines to ensure optimal performance.

References

1.American Chemistry Council. (2021). "Polyurethanes in Building and Construction."

2.U.S. Department of Energy. (2022). "Insulation Materials."

3.Building Science Corporation. (2020). "Guide to Insulating Sheathing."

4.National Institute of Building Sciences. (2021). "Whole Building Design Guide: Insulation."