- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Can Thermal Insulation Wall Panels Enhance Fire Safety in Construction?

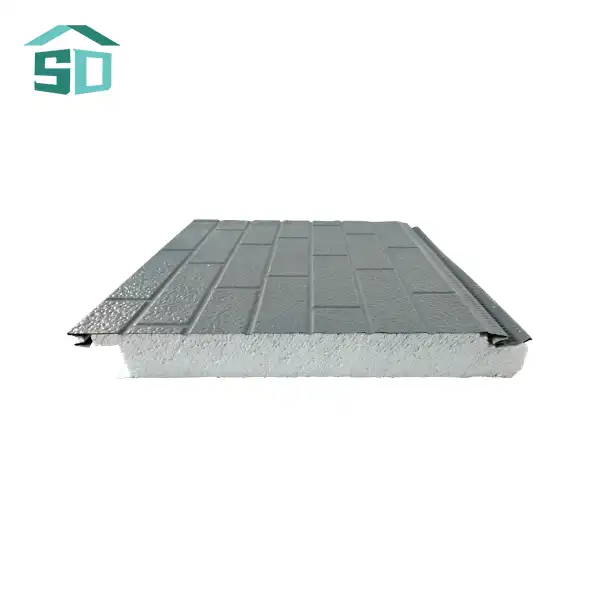

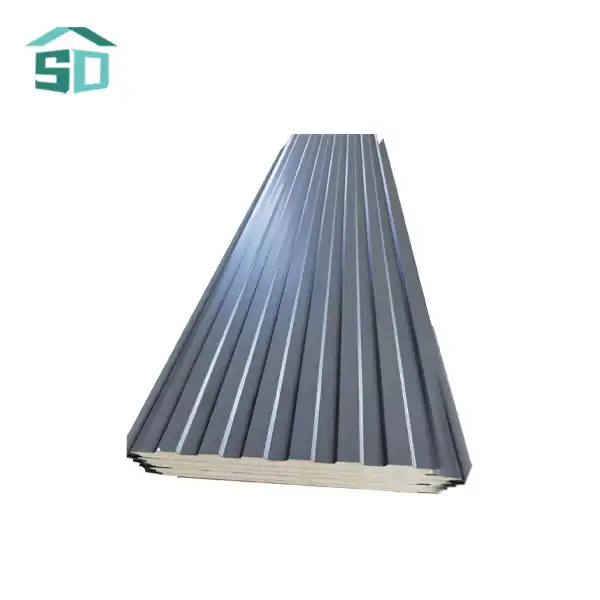

Thermal insulation wall panels have revolutionized the construction industry by offering superior energy efficiency and temperature control. However, their impact on fire safety is a crucial consideration for builders and property owners. The good news is that modern thermal insulation wall panels can indeed enhance fire safety in construction when properly designed and installed. These panels are engineered with fire-resistant materials and undergo rigorous testing to meet stringent fire safety standards. By incorporating flame-retardant properties and acting as a barrier to slow fire spread, thermal insulation wall panels contribute significantly to overall building safety, potentially buying valuable time for evacuation and firefighting efforts in the event of a fire.

The Fire-Resistant Properties of Thermal Insulation Wall Panels

Thermal insulation wall panels are not just about keeping buildings warm in winter and cool in summer. They play a crucial role in fire safety too. Modern panels are designed with fire resistance in mind, utilizing materials that can withstand high temperatures and slow the spread of flames.

Fire-Resistant Materials

The core of thermal insulation wall panels often consists of materials like mineral wool, polyisocyanurate (PIR), or phenolic foam. These materials have inherent fire-resistant properties. For instance, mineral wool can withstand temperatures up to 1000°C without melting, making it an excellent choice for fire-safe construction. PIR foam, while combustible, is formulated to char when exposed to fire, creating a protective layer that slows fire spread.

Fire Ratings and Standards

Thermal insulation wall panels undergo rigorous testing to achieve fire ratings. These ratings, such as A1, A2, B1, and B2 according to ISO 11925-2, indicate the panel's performance in fire conditions. The higher the rating, the better the fire resistance. For example, A1-rated panels are non-combustible and provide the highest level of fire protection. Builders and architects can choose panels with appropriate fire ratings based on the specific requirements of their projects.

Smoke and Toxicity Reduction

In addition to resisting flames, many thermal insulation wall panels are designed to minimize smoke production and toxic emissions during a fire. This is crucial for occupant safety, as smoke inhalation is often more dangerous than the fire itself. Panels with low smoke production and toxicity can significantly improve evacuation times and reduce the risk of smoke-related injuries.

Installation Techniques for Maximizing Fire Safety

While the inherent properties of thermal insulation wall panels contribute to fire safety, proper installation is equally important to maximize their effectiveness.

Proper Sealing and Joining

Gaps between panels can compromise fire resistance. Professional installers use specialized sealants and joining techniques to ensure a continuous barrier against fire spread. This includes careful attention to panel edges, corners, and intersections with other building elements. Proper sealing not only enhances fire safety but also improves the overall thermal performance of the building envelope.

Integration with Fire Stops

Thermal insulation wall panels should be integrated with fire stops at floor levels and other critical junctions. These fire stops create compartments within the building, limiting the spread of fire and smoke between floors or sections. The seamless integration of panels with fire stops is essential for a comprehensive fire safety strategy.

Compliance with Building Codes

Installation must comply with local building codes and fire safety regulations. This often involves specific requirements for panel thickness, attachment methods, and the use of fire-resistant adhesives. Adhering to these codes ensures that the thermal insulation wall panels perform as intended in fire scenarios and meet legal safety standards.

Long-Term Performance and Maintenance for Fire Safety

The fire safety benefits of thermal insulation wall panels extend beyond initial installation, requiring ongoing attention to maintain their effectiveness.

Regular Inspections

Periodic inspections of thermal insulation wall panels are crucial to identify any damage or degradation that could compromise fire safety. This includes checking for gaps, cracks, or moisture penetration that could affect the panel's fire-resistant properties. Early detection and repair of issues can prevent potential fire hazards.

Durability and Weather Resistance

High-quality thermal insulation wall panels are designed to withstand environmental factors without losing their fire-resistant properties. Features like corrosion-resistant coatings and UV protection help maintain the panels' integrity over time. This durability ensures that the fire safety features remain effective throughout the building's lifespan.

Upgrades and Replacements

As fire safety technology advances, building owners may need to consider upgrading or replacing older thermal insulation wall panels. Newer panels may offer improved fire resistance or comply with updated safety standards. Staying informed about advancements in panel technology can help maintain optimal fire safety in the long term.

Conclusion

Thermal insulation wall panels have proven to be a valuable asset in enhancing fire safety in construction. Their fire-resistant properties, when combined with proper installation and maintenance, provide a robust defense against fire spread. As building technologies continue to evolve, these panels are likely to play an increasingly important role in creating safer, more resilient structures. For those considering thermal insulation wall panels in their construction projects, it's crucial to work with reputable manufacturers and experienced installers to ensure the highest standards of fire safety are met. If you have questions about implementing thermal insulation wall panels in your next project, don't hesitate to reach out to industry experts. For more information on our range of fire-resistant thermal insulation wall panels, contact us at info@sdqsc.com.

FAQ

What is the R-value of thermal insulation wall panels?

The R-value varies depending on the insulation material and thickness. Generally, our panels provide excellent thermal resistance, ensuring maximum energy efficiency.

Are thermal insulation wall panels fire-rated?

Yes, our panels meet various fire safety standards, with options ranging from A1 to B2 fire ratings according to ISO 11925-2.

Can I get samples before placing an order?

Absolutely! We offer samples for you to evaluate the quality and performance of our panels.

How do I ensure proper installation of thermal insulation wall panels?

We provide detailed installation guidelines, and our technical support team is always available for assistance to ensure optimal performance and safety.

What materials are used in thermal insulation wall panels?

Our panels are made from high-quality insulation materials, including polyurethane, polystyrene, rock wool, and glass wool, all designed to meet specific project needs and fire safety requirements.

References

1. National Fire Protection Association. (2021). "NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components."

2. International Organization for Standardization. (2020). "ISO 11925-2:2020 Reaction to fire tests — Ignitability of products subjected to direct impingement of flame — Part 2: Single-flame source test."

3. Babrauskas, V. (2016). "Fire Behavior of Insulated Panels in Large-Scale Tests." Fire Technology, 52(5), 1295-1318.

4. Hidalgo, J. P., Torero, J. L., & Welch, S. (2017). "Fire performance of composite sandwich panel systems." Fire Safety Journal, 91, 1047-1058.

5. European Committee for Standardization. (2018). "EN 13501-1:2018 Fire classification of construction products and building elements - Part 1: Classification using data from reaction to fire tests."