- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Can Honeycomb Panels Handle the Heat?

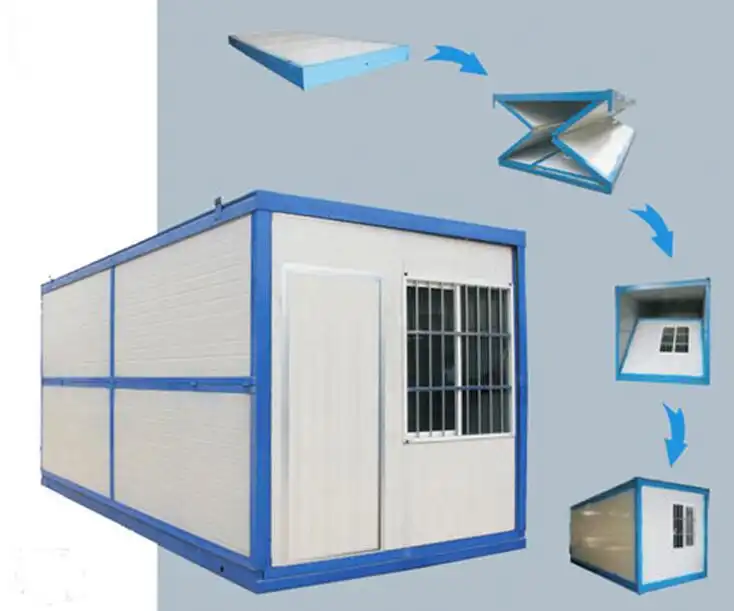

When it comes to thermal performance, honeycomb sandwich panels are indeed capable of handling the heat with remarkable efficiency. These innovative structural components are designed to offer superior insulation properties, making them an excellent choice for both residential and commercial applications where temperature control is crucial. The unique honeycomb core structure creates air pockets that effectively resist heat transfer, while the outer layers provide additional protection. This combination allows honeycomb panels to maintain comfortable interior temperatures even in extreme weather conditions, potentially reducing energy costs and enhancing overall building performance.

The Science Behind Honeycomb Sandwich Panel Heat Resistance

Honeycomb sandwich panels are marvels of engineering, combining strength with lightweight design. Their ability to handle heat stems from their unique structure and the materials used in their construction.

Core Structure and Thermal Insulation

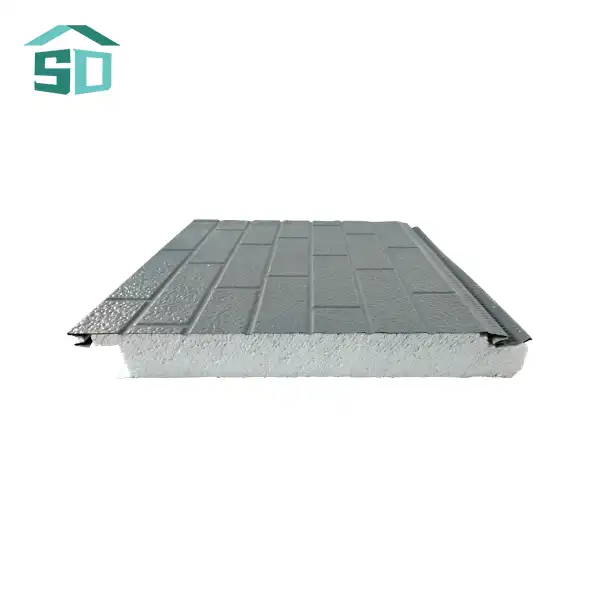

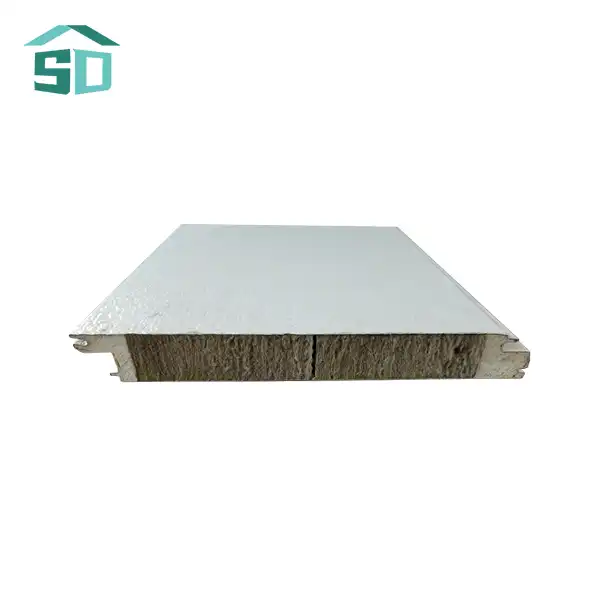

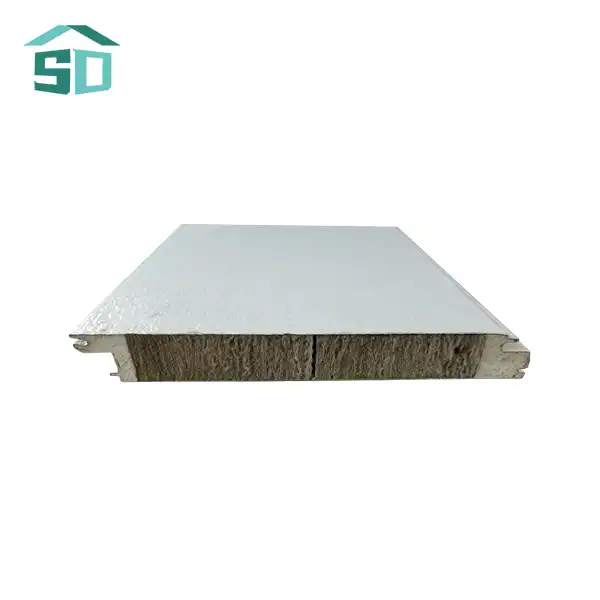

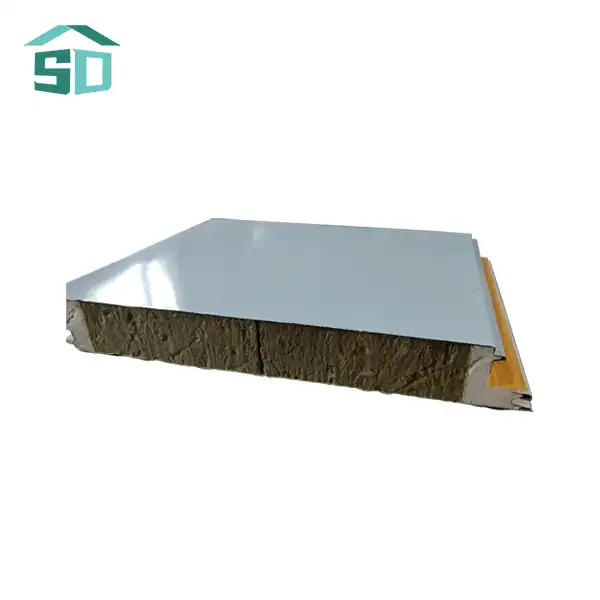

The heart of a honeycomb sandwich panel is its core, which resembles the hexagonal structure found in beehives. This design is not just aesthetically pleasing; it's a triumph of functional engineering. The honeycomb core creates numerous small air pockets, which act as natural insulators. Air is a poor conductor of heat, so these pockets significantly slow down heat transfer through the panel.

Moreover, the core material itself is often made from thermally resistant substances such as aluminum or aramid fiber. These materials have low thermal conductivity, further enhancing the panel's ability to resist heat flow. The thickness of the core can be adjusted to meet specific thermal requirements, allowing for customization based on the intended application.

Face Sheets: The First Line of Defense

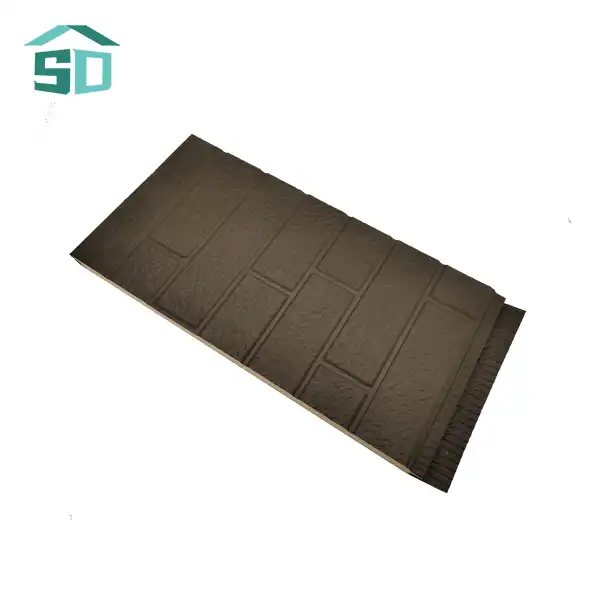

The outer layers, or face sheets, of honeycomb sandwich panels play a crucial role in their heat-handling capabilities. Typically made from materials like aluminum, steel, or fiber-reinforced composites, these sheets provide the initial barrier against thermal energy.

Many face sheets are treated with special coatings or finishes that increase their reflective properties. This means that a significant portion of radiant heat from the sun or other sources is reflected away before it can even penetrate the panel. Some advanced panels even incorporate low-emissivity coatings, which further reduce heat absorption and emission.

Thermal Bridges: Minimized for Maximum Efficiency

One of the key advantages of honeycomb sandwich panels in thermal management is their ability to minimize thermal bridges. Thermal bridges are areas in a structure where heat can easily transfer due to a break in insulation or the use of highly conductive materials.

The design of honeycomb panels inherently reduces these bridges. The continuous core structure ensures that there are no direct pathways for heat to travel from one face sheet to the other. This uniformity in insulation across the entire panel surface results in superior thermal performance compared to many traditional building materials.

Practical Applications: Honeycomb Panels in High-Temperature Environments

The impressive heat-handling capabilities of honeycomb sandwich panels make them suitable for a wide range of applications where temperature control is critical.

Aerospace and Aviation

In the aerospace industry, where materials must withstand extreme temperature fluctuations, honeycomb panels shine. They are used in aircraft fuselages, wings, and interior components. The panels help maintain comfortable cabin temperatures while also protecting sensitive equipment from the intense cold at high altitudes and the heat generated during high-speed flight.

Industrial Ovens and Kilns

Honeycomb panels find application in the construction of industrial ovens and kilns. Their excellent insulation properties help maintain consistent temperatures inside these high-heat environments while keeping the exterior cool. This not only improves energy efficiency but also enhances safety for operators working around the equipment.

Building Facades in Hot Climates

In regions with intense sunlight and high temperatures, honeycomb sandwich panels are increasingly used in building facades. They help create a thermal barrier between the harsh exterior environment and the interior spaces, reducing the load on air conditioning systems and improving overall energy efficiency.

Advancements in Honeycomb Panel Technology for Enhanced Heat Resistance

As demand for more efficient and versatile building materials grows, manufacturers are continuously innovating to improve the heat-handling capabilities of honeycomb sandwich panels.

Phase Change Materials Integration

One of the most exciting developments in honeycomb panel technology is the integration of phase change materials (PCMs). These substances can absorb, store, and release large amounts of latent heat as they change from solid to liquid and back again.

By incorporating PCMs into the honeycomb core or face sheets, panels can provide even greater temperature regulation. During hot periods, the PCMs absorb excess heat, melting in the process. As temperatures cool, the PCMs solidify, releasing the stored heat. This cyclical process helps maintain a more stable interior temperature, reducing energy consumption for heating and cooling.

Nano-Enhanced Materials

Nanotechnology is opening up new possibilities for improving the thermal properties of honeycomb panels. Researchers are exploring the use of nanomaterials like carbon nanotubes and graphene to enhance the thermal conductivity or insulation properties of panel components.

For instance, adding a small percentage of graphene to the resin used in composite face sheets can significantly improve their thermal conductivity. This allows for more efficient heat dissipation in applications where managing excess heat is crucial. Conversely, other nano-additives can be used to further enhance the insulating properties of the core material.

Smart Thermal Management Systems

The future of honeycomb sandwich panels may lie in smart, adaptive thermal management systems. These advanced panels could incorporate sensors and responsive materials that adjust their thermal properties based on environmental conditions.

Imagine a building facade made of honeycomb panels that can dynamically alter their insulation properties or reflectivity in response to changing sunlight intensity or interior temperature needs. Such systems could revolutionize energy efficiency in buildings, providing optimal thermal comfort with minimal energy input.

Conclusion

Honeycomb sandwich panels have proven their mettle when it comes to handling heat. Their unique structure, combined with advanced materials and innovative designs, makes them an excellent choice for applications requiring superior thermal management. As technology continues to advance, we can expect even more impressive heat-handling capabilities from these versatile panels.

For those seeking cutting-edge exterior cladding and facade solutions that offer outstanding thermal performance, Weifang Sandong Building Materials Co., Ltd. is at the forefront of innovation. Our commitment to quality and advanced manufacturing processes ensures that our honeycomb sandwich panels meet the highest standards of thermal efficiency and durability. To learn more about how our products can enhance your next project, don't hesitate to reach out to us at info@sdqsc.com.

References

1. Bitzer, T. (1997). Honeycomb Technology: Materials, Design, Manufacturing, Applications and Testing. Springer Netherlands.

2. Davies, J. M. (2001). Lightweight Sandwich Construction. Wiley-Blackwell.

3. Hexcel Corporation. (2020). HexWeb® Honeycomb Attributes and Properties. Retrieved from Hexcel Technical Data Sheet.

4. Mallick, P. K. (2007). Fiber-Reinforced Composites: Materials, Manufacturing, and Design. CRC Press.

5. Zenkert, D. (1997). The Handbook of Sandwich Construction. Engineering Materials Advisory Services Ltd.