Understanding PU Insulation Board Specifications

Material Composition and Performance

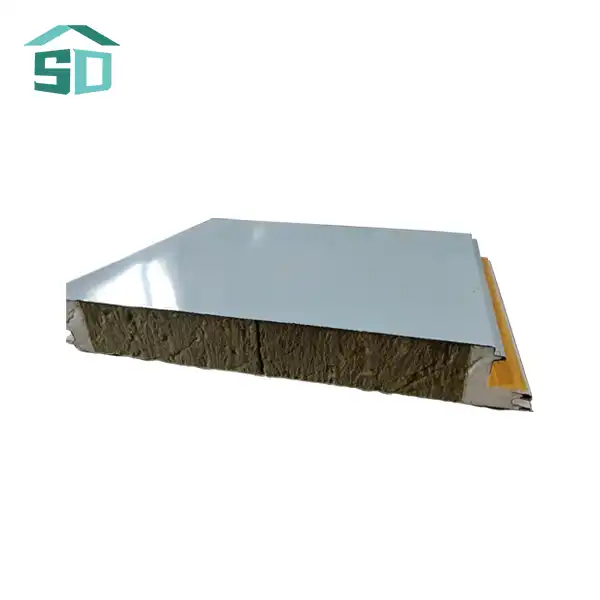

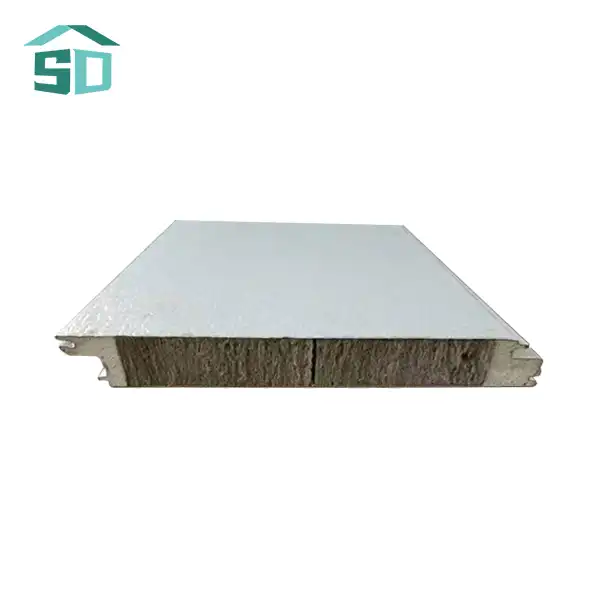

PU insulation boards are made from polyurethane foam, a versatile material known for its exceptional thermal insulation properties. When purchasing PU insulation boards in bulk, it's essential to understand the specific composition and performance characteristics of the product. High-quality PU insulation boards should offer superior thermal resistance, with a thermal conductivity rating of around 0.022 W/m·K. This low thermal conductivity ensures that the boards effectively minimize heat transfer, leading to improved energy efficiency in buildings.

Additionally, reputable PU insulation board factories incorporate advanced manufacturing techniques to enhance the boards' overall performance. These may include the use of specialized blowing agents and optimized cell structures to further improve insulation capabilities. When evaluating bulk purchases, inquire about the specific technologies and materials used in the production process to ensure you're getting the best possible product for your customers.

Dimensions and Customization Options

PU insulation boards typically come in standard sizes, with common dimensions being 1200mm x 2400mm. However, when buying in bulk, you may have the opportunity to request customized sizes to better suit your clients' needs. Consider the most frequently requested dimensions in your market and discuss options for custom cuts with your PU insulation board supplier.

Thickness is another crucial factor to consider. PU insulation boards are available in various thicknesses, commonly ranging from 25mm to 100mm. The appropriate thickness depends on the specific insulation requirements of the project. When purchasing in bulk, it's advisable to stock a range of thicknesses to cater to different customer needs. This versatility will allow you to serve a broader client base and potentially increase your sales volume.

Fire Safety and Regulatory Compliance

Fire safety is a paramount concern in the construction industry, and PU insulation boards must meet stringent fire safety standards. When buying in bulk, ensure that the PU insulation boards you're purchasing have been tested and certified to meet relevant fire safety regulations. Look for products with a Class B1 fire rating, which indicates that the material is non-combustible and suitable for use in a wide range of building applications.

It's also important to verify that the PU insulation boards comply with local building codes and regulations. This may include certifications for environmental sustainability, VOC emissions, and other performance criteria. By stocking products that meet or exceed regulatory requirements, you can position yourself as a trusted supplier of high-quality, compliant building materials.

Evaluating PU Insulation Board Suppliers

Production Capacity and Quality Control

When considering bulk purchases of PU insulation boards, it's crucial to partner with a supplier that has the production capacity to meet your needs consistently. Look for PU insulation board factories equipped with advanced production lines and robust quality control systems. These facilities should have strict testing protocols in place for all components of the PU insulation boards, including the polyurethane foam, facing materials, and any additional treatments or coatings.

Quality control measures should encompass comprehensive inspections of product thickness, mechanical strength, flame retardancy, and overall appearance. By choosing a supplier with rigorous quality assurance processes, you can minimize the risk of receiving subpar products that could damage your reputation or lead to customer dissatisfaction.

Supply Chain Reliability and Lead Times

Reliable supply chain management is essential when dealing with bulk orders of PU insulation boards. Evaluate potential suppliers based on their ability to maintain consistent inventory levels and meet delivery deadlines. Consider factors such as production lead times, shipping logistics, and the supplier's track record for on-time deliveries.

It's also worth inquiring about the supplier's contingency plans for dealing with potential disruptions in the supply chain. A robust PU insulation board factory should have strategies in place to mitigate the impact of raw material shortages, transportation delays, or other unforeseen circumstances that could affect their ability to fulfill your bulk orders.

Technical Support and Product Innovation

As a distributor, you'll likely field questions from customers about the technical aspects of PU insulation boards. Choose a supplier that offers comprehensive technical support and has a team of knowledgeable professionals who can assist with product selection, installation guidance, and troubleshooting.

Additionally, consider the supplier's commitment to innovation and product development. The construction industry is constantly evolving, with new technologies and performance requirements emerging regularly. A forward-thinking PU insulation board factory will invest in research and development to improve their products and stay ahead of market trends. This innovation can give you a competitive edge by allowing you to offer cutting-edge solutions to your customers.

Optimizing Bulk Purchase Strategies

Volume Discounts and Pricing Structures

One of the primary advantages of buying PU insulation boards in bulk is the potential for significant cost savings. When negotiating with suppliers, inquire about their volume discount structures and pricing tiers. Many PU insulation board factories offer progressive discounts based on order quantity, allowing you to reduce your per-unit costs as you increase your purchase volume.

However, it's important to balance the desire for cost savings with practical considerations such as storage capacity and inventory turnover. Analyze your sales data and market projections to determine the optimal order quantity that maximizes discounts while minimizing the risk of overstocking.

Storage and Inventory Management

Proper storage is crucial for maintaining the quality and performance of PU insulation boards. When buying in bulk, ensure you have adequate storage facilities that protect the boards from moisture, UV exposure, and physical damage. Consider factors such as temperature control, ventilation, and proper stacking techniques to preserve the integrity of the PU insulation boards.

Implement an effective inventory management system to track stock levels, monitor product turnover, and optimize reordering processes. This will help you maintain a balanced inventory that meets customer demand without tying up excessive capital in slow-moving stock.

Diversifying Product Offerings

While focusing on bulk purchases of PU insulation boards, consider diversifying your product range to offer complementary items. This might include accessories such as adhesives, sealants, and fasteners specifically designed for use with PU insulation boards. By providing a comprehensive solution, you can increase your value proposition to customers and potentially boost your overall sales.

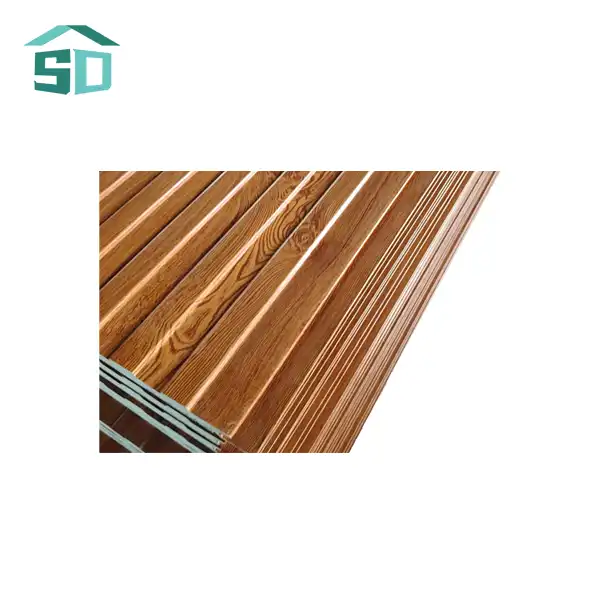

Additionally, explore opportunities to stock PU insulation boards with different facing materials or specialized coatings to cater to specific application requirements. This product diversity can help you tap into niche markets and differentiate your offerings from competitors.

Conclusion

Buying PU insulation boards in bulk requires careful consideration of various factors, from product specifications and supplier reliability to storage logistics and inventory management. By thoroughly evaluating these aspects and implementing strategic purchasing practices, distributors can optimize their operations and position themselves as trusted suppliers of high-quality insulation solutions. Remember that successful bulk purchasing is not just about securing the lowest price, but also about ensuring consistent product quality, reliable supply, and excellent customer service.

Are you ready to elevate your distribution business with top-quality PU insulation boards? At Weifang Sandong Building Materials Co., Ltd., we offer premium PU insulation boards that combine superior thermal performance, fire safety, and durability. Our state-of-the-art production facilities and rigorous quality control ensure that you receive consistent, high-performance products with every order. To learn more about our bulk purchasing options and how we can support your business growth, contact us today at info@sdqsc.com. Let's work together to meet the growing demand for energy-efficient building materials!

FAQs

What is the typical R-value of PU insulation boards?

PU insulation boards generally have an R-value of 6-7 per inch of thickness, making them highly efficient insulators.

How long do PU insulation boards typically last?

When properly installed and maintained, PU insulation boards can last for 50 years or more.

Are PU insulation boards environmentally friendly?

Modern PU insulation boards are produced with eco-friendly blowing agents and can contribute to energy efficiency in buildings, reducing overall environmental impact.

Can PU insulation boards be recycled?

While recycling options for PU insulation boards are limited, some manufacturers offer take-back programs for proper disposal or repurposing.

How do PU insulation boards compare to other insulation materials?

PU insulation boards generally offer higher R-values per inch compared to materials like fiberglass or mineral wool, allowing for thinner wall assemblies while maintaining excellent insulation performance.

References

1. Building Science Corporation. (2021). Thermal Performance of Insulation Materials.

2. International Energy Agency. (2022). Energy Efficiency in Buildings Report.

3. National Institute of Standards and Technology. (2020). Fire Performance of Insulation Materials.

4. American Society for Testing and Materials. (2023). Standard Specification for Rigid Cellular Polyurethane Thermal Insulation.

5. U.S. Department of Energy. (2022). Insulation Materials and Their Properties.