Introducing the Composition and Benefits of Metal Sheet PU Sandwich Panels

The Structural Makeup of Metal Sheet PU Sandwich Panels

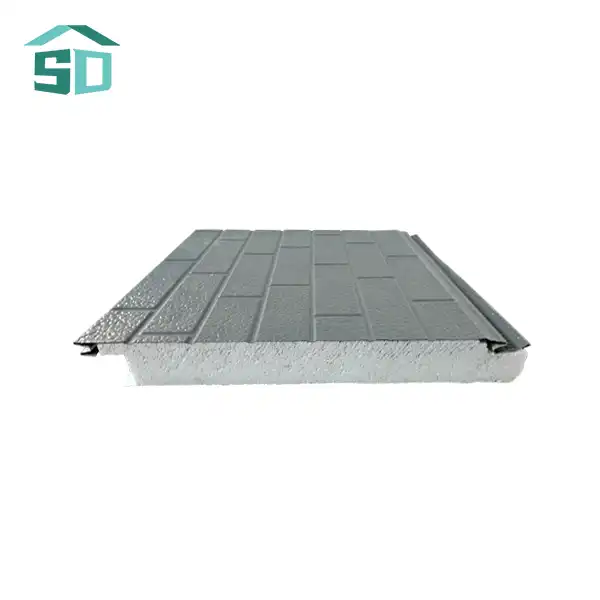

Metal sheet PU sandwich panels are a marvel of modern construction technology, engineered to provide optimal performance in various applications, including cold storage. These panels consist of three primary components: two metal sheets serving as the outer layers and a core of polyurethane foam. The metal sheets, typically made of high-quality steel or aluminum, offer exceptional durability and strength. These sheets can vary in thickness, with common options ranging from 0.23mm to 0.27mm, allowing for customization based on specific project requirements.

The heart of the panel lies in its polyurethane core, a sophisticated insulation material that boasts remarkable thermal properties. This core is the key to the panel's impressive thermal conductivity of 0.018W/m.k, ensuring minimal heat transfer and maximum energy efficiency. The thickness of the PU core can be tailored to meet different insulation needs, with options ranging from 10mm for interior applications to 16mm or 20mm for exterior use.

Advantages of Metal Sheet PU Sandwich Panels in Cold Storage

The benefits of using metal sheet PU sandwich panels in cold storage applications are numerous and significant. Foremost among these is their superior thermal insulation capability. With a thermal resistance of 2.09m2k/w, these panels create an effective barrier against temperature fluctuations, maintaining the desired cold environment with minimal energy expenditure. This translates to substantial cost savings in the long run, as cold storage facilities can operate more efficiently and with reduced energy consumption.

Durability is another hallmark of these panels. The metal sheet exterior provides excellent resistance to physical damage, while the PU core offers stability and longevity. This durability is further enhanced by the panels' corrosion-resistant properties, allowing them to withstand harsh environments often associated with cold storage facilities. The panels boast a compressive strength of 52.7kpa, ensuring they can handle the rigors of industrial applications without compromising their structural integrity.

Safety is paramount in any storage facility, and metal sheet PU sandwich panels excel in this aspect as well. With a fire-protection rating of B1/B2, these panels offer enhanced fire resistance, contributing to a safer storage environment. Additionally, their waterproof rate of 0.0008 ensures protection against moisture intrusion, a critical factor in maintaining the integrity of stored goods and preventing the growth of mold and mildew.

Optimizing Cold Storage Efficiency with Metal Sheet PU Sandwich Panels

Thermal Performance and Energy Savings

The thermal efficiency of metal sheet PU sandwich panels is a game-changer for cold storage applications. The low thermal conductivity of 0.018W/m.k ensures that the cold air remains inside the storage area, minimizing the workload on refrigeration systems. This superior insulation translates to significant energy savings, as cooling systems can operate less frequently and at lower intensities to maintain the desired temperature.

Moreover, the thermal resistance of 2.09m2k/w offered by these panels creates a formidable barrier against external heat. This resistance is particularly crucial in regions with high ambient temperatures or in facilities where temperature control is critical for product integrity. By effectively mitigating heat transfer, metal sheet PU sandwich panels help maintain consistent internal temperatures, reducing the risk of temperature fluctuations that could compromise stored goods.

Customization for Specific Cold Storage Needs

One of the most compelling features of metal sheet PU sandwich panels is their adaptability to various cold storage requirements. The panels can be customized in terms of length, width, and thickness to fit specific architectural designs and insulation needs. For exterior applications, panels with widths of 383mm and thicknesses of 16mm or 20mm are commonly used, providing robust insulation for larger cold storage facilities. Interior applications often utilize panels with a width of 450mm and a thickness of 10mm, offering a balance between space efficiency and insulation performance.

This customization extends beyond dimensions to aesthetic considerations as well. The metal sheet exterior can be tailored with various colors and patterns, allowing cold storage facilities to maintain a professional and appealing appearance while benefiting from top-tier insulation. This versatility makes metal sheet PU sandwich panels an ideal choice for both new constructions and retrofitting existing cold storage spaces.

Installation and Maintenance of Metal Sheet PU Sandwich Panels in Cold Storage

Efficient Installation Process

The installation of metal sheet PU sandwich panels in cold storage applications is a streamlined process that contributes to their overall efficiency and cost-effectiveness. These panels are designed for ease of handling and quick assembly, reducing construction time and labor costs. The lightweight nature of the panels, combined with their structural integrity, allows for rapid installation without the need for heavy machinery or extensive support structures.

The interlocking design of these panels ensures a tight seal between units, crucial for maintaining the thermal barrier in cold storage environments. This design also contributes to the panels' impressive wind resistance of 8.0 Kpa, making them suitable for both interior and exterior applications. The seamless integration of panels minimizes thermal bridges, further enhancing the overall insulation performance of the cold storage facility.

Long-Term Maintenance and Durability

One of the most appealing aspects of metal sheet PU sandwich panels is their low maintenance requirements, making them an ideal choice for long-term cold storage applications. The metal exterior is resistant to corrosion and physical damage, requiring minimal upkeep to maintain its structural and aesthetic integrity. Regular cleaning with mild detergents is typically sufficient to keep the panels in optimal condition.

The durability of these panels extends to their core components as well. The polyurethane foam core maintains its insulation properties over time, resisting degradation that can occur with other insulation materials. This long-term performance ensures that cold storage facilities can operate efficiently for years without the need for frequent replacements or repairs.

Furthermore, the panels' resistance to moisture, with a waterproof rate of 0.0008, prevents issues commonly associated with cold storage environments, such as condensation buildup and mold growth. This resistance not only protects the panels themselves but also safeguards the stored goods, maintaining a clean and hygienic storage environment.

Conclusion

Metal sheet PU sandwich panels represent the pinnacle of cold storage technology, offering a perfect blend of thermal efficiency, durability, and customization. Their superior insulation properties, coupled with ease of installation and low maintenance requirements, make them an invaluable asset for any cold storage facility looking to optimize performance and reduce operating costs. As the demand for energy-efficient and reliable cold storage solutions continues to grow, metal sheet PU sandwich panels stand ready to meet and exceed these needs, ensuring the preservation of goods in a controlled environment while minimizing energy consumption and environmental impact.

For more information on how metal sheet PU sandwich panels can revolutionize your cold storage applications, or to explore our range of exterior cladding and facade solutions, please contact us at info@sdqsc.com. Let Weifang Sandong Building Materials Co., Ltd. help you create the most efficient and effective cold storage solution for your unique needs.