Key Features of Top-Performing Insulated Sandwich Wall Panels

Superior Thermal Insulation Properties

The cornerstone of any effective cold storage facility lies in its ability to maintain consistent low temperatures. Insulated sandwich wall panels excel in this aspect, thanks to their advanced thermal insulation properties. With a thermal conductivity as low as 0.018 W/m.K, these panels create a formidable barrier against heat transfer, ensuring that the interior of the cold storage facility remains at the desired temperature regardless of external conditions.

The thermal resistance of these panels, typically around 2.09 m²K/W, further enhances their insulation capabilities. This high thermal resistance translates to reduced energy consumption, as less power is required to maintain the cold environment. The result is not only improved energy efficiency but also significant cost savings over the lifetime of the facility.

Durability and Structural Integrity

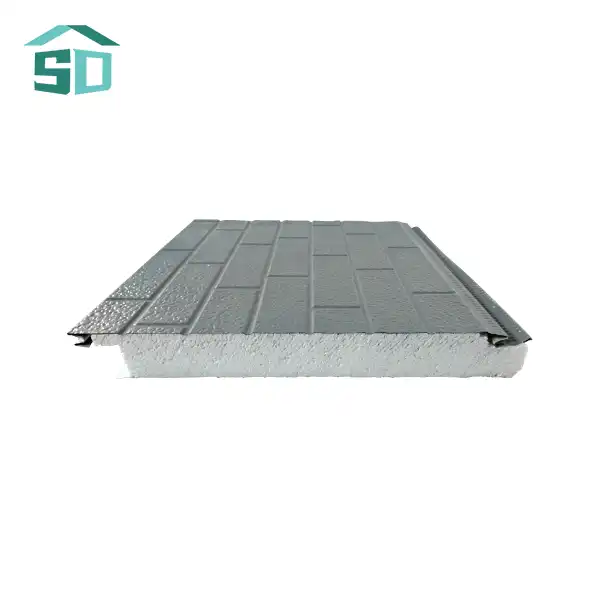

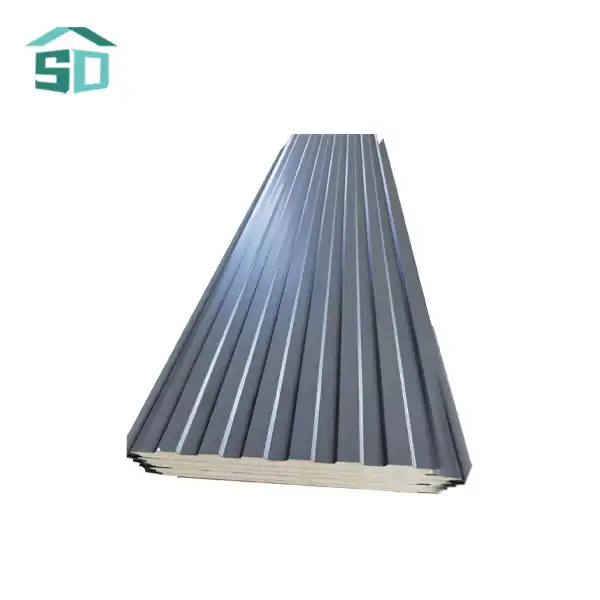

Cold storage facilities often operate in challenging environments, making the durability of insulated sandwich wall panels a critical factor. These panels are designed to withstand harsh conditions, including temperature fluctuations, moisture, and physical impacts. The exterior layers, typically made of steel or aluminum with thicknesses ranging from 0.23mm to 0.27mm, provide robust protection against external elements.

The panels' compressive strength, which can reach up to 52.7 kPa, ensures they can support substantial loads without deformation. This structural integrity is crucial for maintaining the facility's overall stability and preserving the integrity of the cold chain. Additionally, the panels' wind resistance of 8.0 kPa makes them suitable for use in areas prone to high winds, further expanding their applicability in various geographical locations.

Moisture Resistance and Fire Safety

Moisture control is essential in cold storage environments to prevent frost formation and maintain hygiene standards. High-quality insulated sandwich wall panels boast impressive waterproof ratings, with some models achieving a rate as low as 0.0008. This exceptional water resistance helps prevent moisture ingress, which could otherwise compromise the insulation effectiveness and lead to structural degradation over time.

Fire safety is another crucial aspect, especially given the valuable contents often stored in cold storage facilities. The best insulated sandwich wall panels come with fire-protection ratings of B1 or B2, indicating their ability to resist fire spread and contribute to overall building safety. This feature not only enhances the protection of stored goods but also helps facilities comply with stringent safety regulations.

Installation and Customization Options

Efficient Installation Process

One of the key advantages of using insulated sandwich wall panels in cold storage construction is their ease of installation. The installation process is straightforward and efficient, typically following these steps:

1.Preparation: Ensure the installation surface is clean, dry, and free from debris to create a solid foundation.

2.Layout Planning: Carefully plan the panel arrangement according to the building design, optimizing for thermal performance and structural integrity.

3.Fastening: Use appropriate fasteners to secure the panels in place, ensuring a tight fit that maximizes insulation effectiveness.

4.Sealing: Apply high-quality sealants at panel joints and connections to prevent air and water ingress, maintaining the integrity of the thermal envelope.

5.Finishing: Complete the installation with any necessary surface treatments or finishes to enhance durability and aesthetic appeal.

This efficient installation process not only reduces construction time but also minimizes the potential for errors that could compromise the facility's thermal performance.

Customization Options for Specific Requirements

Cold storage facilities often have unique requirements based on their specific use case, geographical location, and regulatory environment. The best insulated sandwich wall panels offer a range of customization options to meet these diverse needs:

- Panel Dimensions: Panels can be customized in length, with typical widths of 383mm for exterior applications and 450mm for interior use. Thickness options usually range from 10mm for interior panels to 16mm or 20mm for exterior applications.

- Surface Materials: The choice of surface materials and thicknesses (0.23mm, 0.25mm, or 0.27mm) allows for optimization based on the specific environmental challenges and aesthetic preferences.

- Color and Finish: A wide range of colors and patterns are available, enabling the creation of visually appealing facilities that align with corporate branding or local architectural styles.

- Insulation Core: The type and density of the insulation core can be adjusted to meet specific thermal performance requirements or to comply with local building codes.

This level of customization ensures that cold storage facilities can be tailored to meet exact specifications, optimizing performance and efficiency.

Long-Term Benefits and Cost-Effectiveness

Energy Efficiency and Operational Cost Reduction

The superior insulation properties of high-quality sandwich wall panels translate directly into significant energy savings over the life of a cold storage facility. By maintaining consistent internal temperatures with minimal heat transfer, these panels reduce the workload on cooling systems, leading to lower energy consumption and reduced operational costs.

The thermal conductivity of 0.018 W/m.K ensures that cold air remains inside the facility, while the high thermal resistance of 2.09 m²K/W effectively blocks external heat. This thermal efficiency is particularly crucial in regions with extreme temperature variations, where maintaining stable internal conditions can be challenging and energy-intensive.

Durability and Low Maintenance Requirements

The durability of insulated sandwich wall panels contributes significantly to their long-term cost-effectiveness. The corrosion-resistant properties of the exterior surfaces, combined with the panels' inherent structural stability, result in a longer lifespan with minimal maintenance requirements. This durability is especially valuable in cold storage environments, where constant temperature cycling and potential moisture issues can accelerate wear and tear on less robust materials.

The panels' resistance to moisture, with a waterproof rate of 0.0008, not only protects the insulation core but also prevents the growth of mold and mildew, further reducing maintenance needs and ensuring a hygienic storage environment. This combination of durability and low maintenance translates into reduced lifecycle costs and improved return on investment for cold storage facility operators.

Adaptability and Future-Proofing

As the cold storage industry evolves, facilities must be able to adapt to changing requirements and technologies. The modular nature of insulated sandwich wall panels provides inherent flexibility, allowing for relatively easy modification or expansion of facilities as needs change. This adaptability extends the useful life of the structure and helps future-proof investments in cold storage infrastructure.

Moreover, the eco-friendly nature of many modern insulated sandwich wall panels aligns with growing environmental concerns and regulations. By choosing panels with sustainable materials and production processes, facility owners can ensure compliance with current and future environmental standards, potentially avoiding costly retrofits or penalties.

Conclusion

The best insulated sandwich wall panels for cold storage facilities offer a compelling combination of thermal efficiency, durability, and cost-effectiveness. Their superior insulation properties, coupled with ease of installation and customization options, make them an ideal choice for constructing high-performance cold storage environments. By investing in quality insulated sandwich wall panels, facility owners can ensure optimal temperature control, energy efficiency, and long-term operational success.

For more information on cutting-edge insulated sandwich wall panels and other exterior cladding solutions, please contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is ready to assist you in finding the perfect solution for your cold storage facility needs.