Understanding the Composition and Benefits of Metal Sheet PU Sandwich Panels

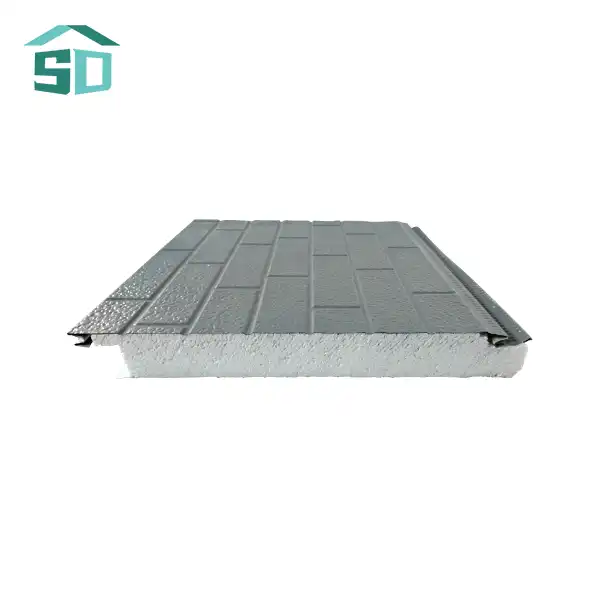

The Anatomy of a Metal Sheet PU Sandwich Panel

Metal sheet PU sandwich panels are a marvel of modern construction technology. These panels consist of two high-strength metal sheets encasing a core of polyurethane foam. The metal sheets, typically 0.23mm to 0.27mm thick, provide structural integrity and protection against external elements. The PU core, available in thicknesses ranging from 10mm for interior applications to 16mm or 20mm for exterior use, offers exceptional insulation properties.

The unique composition of these panels results in a product that is both lightweight and incredibly strong. With a compressive strength of 52.7kpa, these panels can withstand significant loads while maintaining their structural integrity. This combination of quality and gentility makes them perfect for a wide run of development applications, from private complexes to commercial buildings.

Fire Resistance: A Critical Feature

One of the standout features of metal sheet PU sandwich panels is their impressive fire resistance. With a fire-protection rating of B1/B2, these boards essentially impede the spread of blazes in the occasion of a fire. This rating indicates that the panels have undergone rigorous testing and have demonstrated their ability to resist ignition and limit fire propagation.

The fire-resistant properties of these panels are not just a matter of safety compliance; they provide real-world protection. On the occasion of a fire, these boards can purchase valuable time for tenants to clear and for firefighters to react, possibly sparing lives and minimizing property harm.

Thermal Efficiency and Energy Savings

Beyond fire resistance, metal sheet PU sandwich panels offer exceptional thermal insulation properties. With a thermal conductivity of just 0.018W/m.k and a thermal resistance of 2.09m2k/w, these panels create a formidable barrier against heat transfer. This deciphers to critical vitality reserve funds in both warming and cooling, making buildings more energy-efficient and naturally inviting.

The superior insulation properties of these panels contribute to a more comfortable indoor environment year-round. By reducing heat gain in summer and heat loss in winter, they help maintain consistent indoor temperatures, reducing the load on HVAC systems and lowering energy costs.

Durability and Versatility: Key Advantages of Metal Sheet PU Sandwich Panels

Weather Resistance and Longevity

Metal sheet PU sandwich panels are engineered to withstand harsh environmental conditions. With a waterproof rate of 0.0008, these panels provide excellent protection against moisture infiltration, preventing water damage and mold growth. Their corrosion-free performance ensures that they maintain their integrity and appearance even in challenging environments, such as coastal areas or industrial zones.

The panels' wind resistance of 8.0 Kpa demonstrates their ability to withstand high wind loads, making them suitable for use in areas prone to severe weather conditions. This durability translates to lower maintenance costs and a longer lifespan for the building envelope, providing long-term value for property owners.

Aesthetic Flexibility and Design Options

While performance is crucial, aesthetics play a significant role in modern architecture. Metal sheet PU sandwich panels offer a wide range of customization options, allowing architects and designers to create visually striking buildings. These boards can be custom-made with different colors, surfaces, and designs to upgrade any plan stylish, from smooth and advanced to conventional and classic.

The versatility of these panels extends to their application. With widths of 383mm for exterior use and 450mm for interior applications, they can be easily integrated into various architectural styles and building types. Whether used for exterior cladding or interior partitions, these panels provide a seamless and polished look while delivering on performance.

Sustainability and Environmental Considerations

In an era where sustainability is paramount, metal sheet PU sandwich panels offer several eco-friendly advantages. Their energy-efficient properties contribute to reduced carbon emissions over the life of the building. Additionally, the durability and longevity of these panels mean less frequent replacement, reducing waste and resource consumption.

Many manufacturers are now focusing on using recyclable materials in the production of these panels, further enhancing their environmental credentials. The metal components can often be recycled at the end of the panel's life, contributing to a circular economy in the construction industry.

Installation and Maintenance: Maximizing the Performance of Metal Sheet PU Sandwich Panels

Efficient Installation Processes

One of the key advantages of metal sheet PU sandwich panels is their ease of installation. The lightweight nature of these boards, combined with their interlocking plan, permits for fast and proficient establishment. This can altogether diminish development time and labor costs, making them an alluring alternative for both modern builds and redesign ventures.

Proper installation is crucial to maximize the performance of these panels, particularly in terms of fire resistance and insulation. It's essential to follow manufacturer guidelines and local building codes to ensure that the panels are correctly fitted and sealed. This attention to detail during installation helps maintain the integrity of the fire-resistant properties and thermal barrier.

Long-Term Maintenance and Care

While metal sheet PU sandwich panels are designed for durability and low maintenance, proper care can extend their lifespan and preserve their performance. Normal reviews ought to be conducted to check for any signs of harm, especially after extraordinary climate occasions. Any cracks or gaps in the panels should be promptly addressed to maintain their fire-resistant and insulating properties.

Cleaning these panels is typically straightforward, often requiring nothing more than a mild detergent and water. However, it's important to avoid harsh chemicals or abrasive cleaning methods that could damage the panel's surface. With proper maintenance, these panels can maintain their appearance and performance for decades, providing long-term value for building owners.

Future Innovations and Developments

As technology advances, we can expect to see further improvements in the performance and sustainability of metal sheet PU sandwich panels. Research is ongoing into even more fire-resistant coatings and core materials, potentially pushing the fire-protection ratings even higher. Additionally, innovations in recycling technologies may make these panels even more environmentally friendly in the future.

The integration of smart technologies into building materials is another area of potential development. Future iterations of these panels might include sensors for monitoring temperature, humidity, or even air quality, contributing to more intelligent and responsive building systems.

Conclusion

Metal sheet PU sandwich panels represent a significant advancement in building technology, offering a unique combination of fire resistance, thermal efficiency, durability, and aesthetic flexibility. As the development industry proceeds to prioritize security, vitality proficiency, and maintainability, these boards are balanced to play an progressively vital part in making more secure, more versatile buildings.

Their versatility makes them suitable for a wide range of applications, from residential complexes and offices to industrial facilities and public buildings. By choosing metal sheet PU sandwich panels, architects, builders, and property owners can enhance the safety, efficiency, and longevity of their structures while also contributing to more sustainable building practices.

As we look to the future of construction, it's clear that materials like metal sheet PU sandwich panels will be at the forefront of innovation, driving improvements in building performance and safety. For those interested in learning more about these innovative building materials and how they can be incorporated into your next project, we invite you to contact us at info@sdqsc.com. Our team of experts is ready to provide you with detailed information and guidance on selecting the best fire-resistant PU sandwich panels for your specific needs.