Understanding the Structural Capabilities of Sandwich Panels

Sandwich panels, particularly the 10 cm sandwich panel, have revolutionized modern construction with their versatile applications and impressive performance characteristics. While not primarily designed for load-bearing purposes, these panels can play a crucial role in a building's structural integrity when properly integrated.

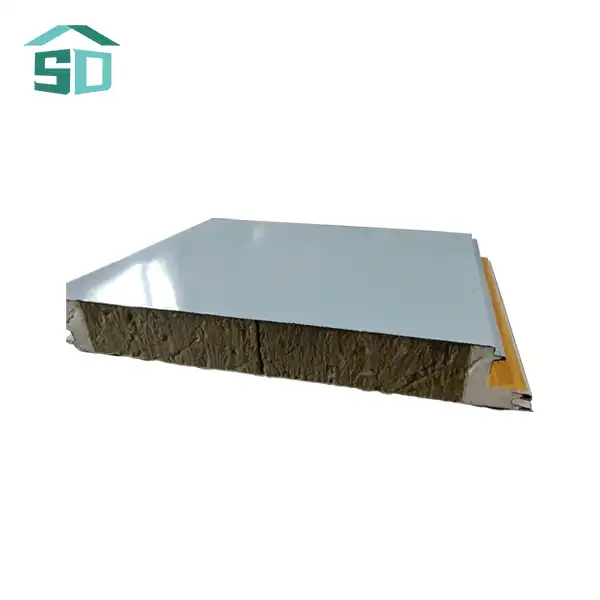

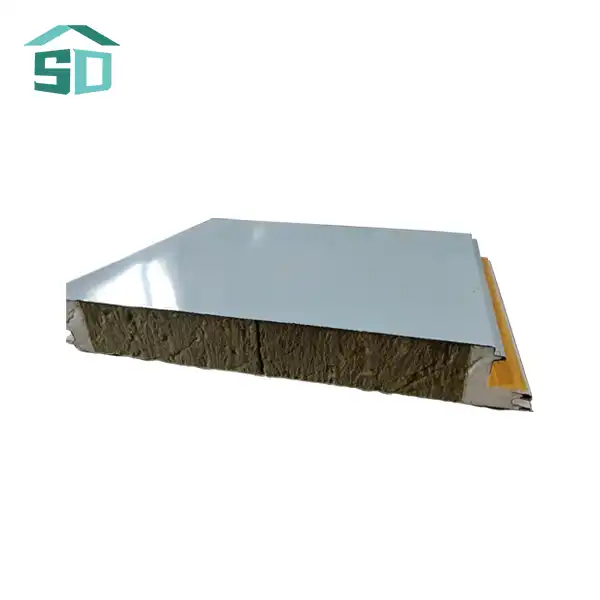

Composition and Strength

The 10 cm sandwich panel is constructed with two durable outer facings—commonly made from materials like galvanized steel, aluminum, or stainless steel—securely bonded to a rigid core. This core may consist of polyurethane (PU), expanded polystyrene (EPS), or rock wool, each offering excellent insulation. The substantial 10 cm thickness adds to the panel's strength and longevity, making it highly suitable for enhancing both interior and exterior building walls in a wide range of applications.

Load Distribution

Although sandwich panels are generally not considered primary load-bearing elements, the 10 cm variant offers improved load distribution capabilities across its surface. This added thickness allows the panel to handle external forces more effectively than thinner options. As a result, these panels are frequently utilized in projects such as residential buildings, public facilities, and office structures, where they enhance overall structural reliability while contributing to aesthetic and functional performance.

Thermal Performance and Energy Efficiency

A major advantage of the 10 cm sandwich panel lies in its impressive thermal insulation properties, which significantly support energy conservation efforts. The thick core acts as a barrier to heat transfer, helping regulate indoor temperatures year-round. This energy efficiency results in lower heating and cooling demands, making the panel an excellent choice for projects seeking to reduce both operating costs and environmental impact over the long term.

Insulation Properties

Thanks to its 10 cm thickness, this type of sandwich panel offers superior insulation that minimizes the exchange of heat between interior and exterior spaces. By slowing down thermal conduction, it helps buildings maintain energy efficiency, cutting down on the need for artificial climate control. This leads not only to noticeable savings on energy bills but also supports environmentally conscious building design through reduced energy consumption and carbon emissions.

Climate Control

A major advantage of 10 cm sandwich panels is their capability to regulate and maintain steady indoor temperatures throughout the year. By effectively protecting interiors from external temperature fluctuations—whether heat, cold, or humidity—they create a comfortable and stable living or working environment in all seasons. This reliable insulation is especially important in areas with harsh or extreme weather conditions, where the panels serve as a protective barrier that improves indoor comfort, preserves air quality, and enhances overall energy efficiency in the building.

Versatility and Customization Options

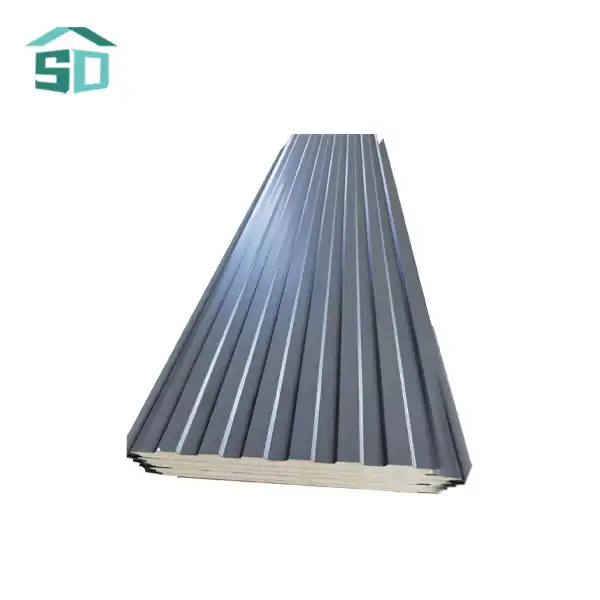

The 10 cm sandwich panel provides a wide range of customization possibilities, making it a highly adaptable option for diverse architectural applications. Whether used in contemporary or traditional designs, these panels can be tailored to suit different creative visions. This flexibility ensures that they meet both aesthetic and functional needs, allowing architects and developers to align building materials with the specific character and identity of each project.

Aesthetic Flexibility

These sandwich panels can be personalized using a broad spectrum of colors and surface textures, enabling the creation of striking and distinctive facades. Utilizing the comprehensive RAL color chart, designers can precisely match the panel finish to a brand’s identity or a specific architectural theme. This level of customization makes the 10 cm panel suitable for projects where visual consistency, branding, or standout architectural expression is a primary concern.

Application Diversity

The functional versatility of 10 cm sandwich panels allows them to be used in a wide variety of construction contexts. Whether for exterior facades or interior partitions, they are ideal for both newly built structures and renovation projects. Their adaptability makes them well-suited for a range of environments, including commercial complexes, industrial buildings, modern office spaces, and even the restoration of historic properties that require modern performance with a traditional appearance.

Durability and Maintenance

One of the standout features of the 10 cm sandwich panel is its exceptional resistance to environmental wear and tear. Engineered to withstand harsh weather conditions, these panels do not easily corrode, fade, or degrade over time, ensuring consistent long-term performance with very little maintenance required. Their sturdy construction minimizes damage caused by exposure to pollution, moisture, and other external factors, helping to preserve both their aesthetic appeal and functional integrity. This durability ultimately reduces repair costs and extends the overall lifespan of the panels, making them a cost-effective choice for building owners.

Conclusion

Although 10 cm sandwich panels are not mainly intended to serve as load-bearing components, their robust construction, excellent thermal insulation, and remarkable versatility make them an essential element in contemporary building design. These panels strike an ideal balance between aesthetics and practicality by offering superior insulation, long-lasting durability, enhanced fire resistance, and a variety of customization options. For architects and builders aiming to improve both the performance and visual appeal of their structures, the 10 cm sandwich panel is a highly effective and visually appealing exterior cladding solution. To learn more about how these innovative panels can benefit your construction project, please contact us at info@sdqsc.com.