The Synergy of Metal and PU: A Game-Changer in Roofing

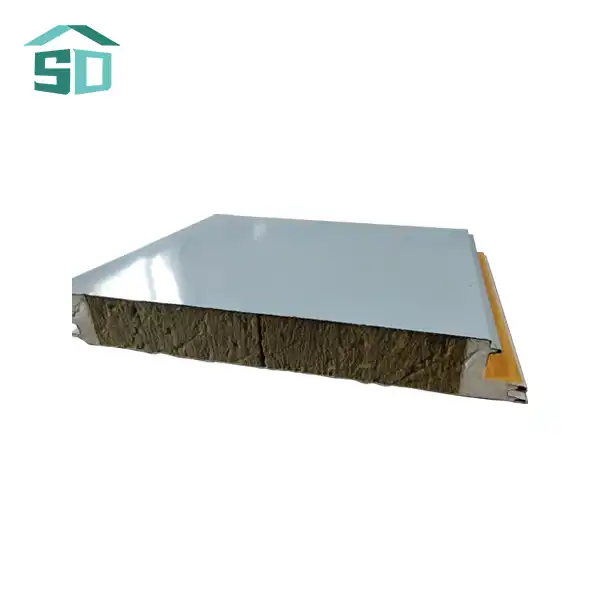

Metal sheet PU sandwich panels represent a revolutionary approach to roofing materials. These panels amalgamate the robustness of metal with the insulating properties of polyurethane, creating a product that's greater than the sum of its parts. The metal exterior provides unparalleled durability, while the PU core offers exceptional insulation.

Unmatched Strength and Stability

The fusion of metal sheets with PU creates a structure of remarkable stability. This combination results in panels that can withstand extreme weather conditions, from heavy snowfall to intense heat. The metal component, typically steel or aluminum, offers resistance to physical impacts, while the PU core provides structural integrity. This synergy ensures that the roofing maintains its form and function over extended periods, even in challenging environments.

Thermal Efficiency: A Key Advantage

One of the standout features of metal sheet PU sandwich panels is their thermal efficiency. With a thermal conductivity of just 0.018W/m.k and a thermal resistance of 2.09m2k/w, these panels significantly outperform traditional roofing materials. This exceptional insulation capability translates to reduced energy costs for heating and cooling, making buildings more energy-efficient and environmentally friendly.

Customization: Blending Functionality with Aesthetics

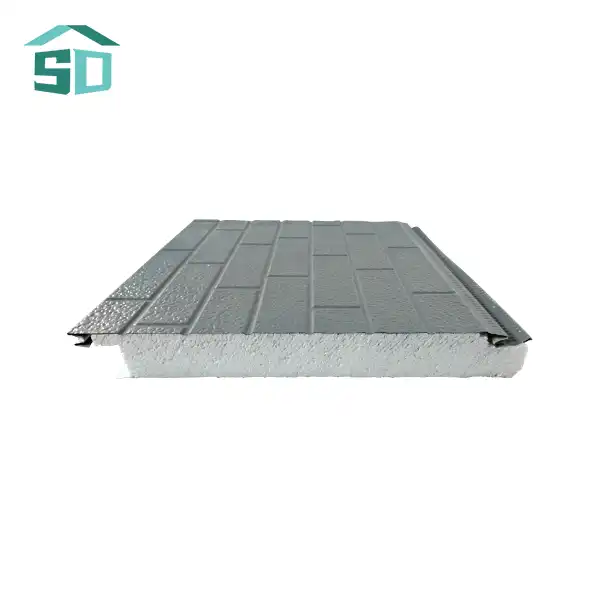

The versatility of metal sheet PU sandwich panels extends to their aesthetic appeal. These panels can be tailored in various colors and patterns, allowing architects and builders to enhance any design concept. Whether it's a sleek, modern look or a more traditional appearance, these panels can be customized to complement the overall architectural vision of a building.

Safety and Durability: Core Strengths of High-Density PU Panels

When it comes to roofing, safety and durability are paramount concerns. High-density PU panels, especially in the form of metal sheet PU sandwich panels, address these concerns comprehensively, offering a range of features that ensure long-lasting protection for buildings.

Fire Resistance: A Critical Safety Feature

One of the most crucial aspects of any roofing material is its fire resistance. Metal sheet PU sandwich panels boast impressive fire-protection ratings of B1/B2, indicating their ability to resist flame spread and contribute to overall building safety. This non-flammable nature is essential in creating safer spaces, particularly in areas prone to wildfires or in buildings where fire safety is a top priority.

Weather Resistance: Standing Up to the Elements

The durability of high-density PU panels is evident in their ability to withstand harsh environmental conditions. With a waterproof rate of 0.0008 and wind resistance of 8.0 Kpa, these panels provide excellent protection against water infiltration and high winds. This resilience ensures that the roofing remains intact and functional even in severe weather events, protecting the building's interior from water damage and structural stress.

Corrosion Resistance: Long-Term Performance

Another significant advantage of metal sheet PU sandwich panels is their resistance to corrosion. This feature is particularly valuable in coastal areas or industrial environments where exposure to salt air or chemical pollutants can rapidly degrade traditional roofing materials. The corrosion-resistant properties of these panels contribute to their longevity, reducing the need for frequent replacements or repairs and thus lowering long-term maintenance costs.

Versatility and Cost-Effectiveness: Making the Case for High-Density PU Panels

The appeal of high-density PU panels, particularly metal sheet PU sandwich panels, extends beyond their technical specifications. Their versatility in application and cost-effectiveness make them an attractive option for a wide range of construction projects.

Adaptability in Design and Application

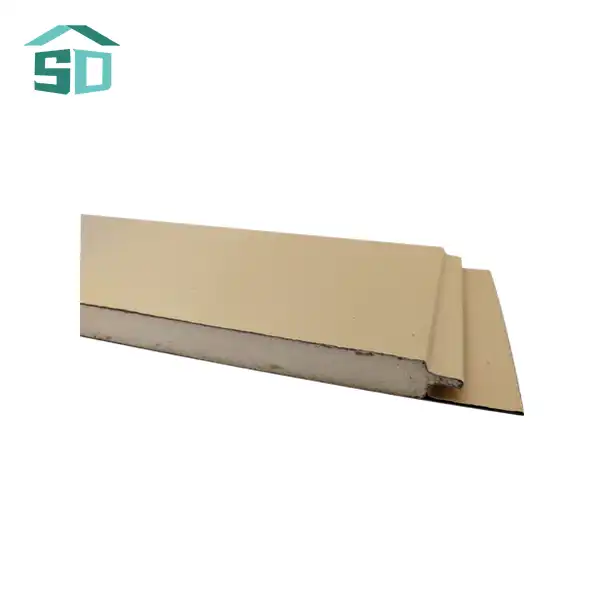

Metal sheet PU sandwich panels are remarkably versatile, suitable for both exterior and interior applications. Their customizable dimensions – with thicknesses ranging from 10mm for interiors to 16mm or 20mm for exteriors, and widths of 383mm for exteriors and 450mm for interiors – allow for flexibility in design and installation. This adaptability makes them ideal for various structures, from residential complexes and offices to villas, gardens, and even historic building renovations.

Economic Benefits: Balancing Quality and Cost

While the initial cost of high-density PU panels might be higher than some traditional roofing materials, their long-term economic benefits are substantial. The durability and low maintenance requirements of these panels translate to reduced lifecycle costs. Moreover, their superior insulation properties contribute to significant energy savings over time, further enhancing their cost-effectiveness.

Eco-Friendly Choice: Aligning with Sustainability Goals

In an era where environmental considerations are increasingly important, metal sheet PU sandwich panels stand out as an eco-friendly choice. Their energy-efficient properties contribute to reduced carbon footprints for buildings. Additionally, the longevity of these panels means less frequent replacements, reducing waste and resource consumption in the long run.

Conclusion

High-density PU panels, especially in the form of metal sheet PU sandwich panels, offer a compelling solution for modern roofing needs. Their combination of strength, insulation, safety features, and versatility positions them as a top choice for a wide range of building projects. While they may not be the only option available, their comprehensive benefits make them an excellent choice for those seeking a balance of performance, durability, and cost-effectiveness in roofing materials.

For those interested in exploring high-quality exterior cladding and facade solutions, including metal sheet PU sandwich panels, Weifang Sandong Building Materials Co., Ltd. offers a range of products tailored to meet diverse construction needs. To learn more about our offerings and how they can enhance your building projects, please contact us at info@sdqsc.com.