The Science Behind Aluminum Foam Sandwich Panel Durability

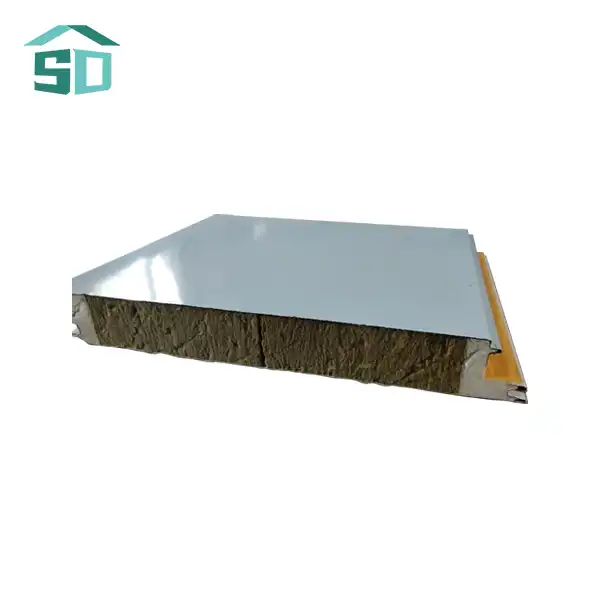

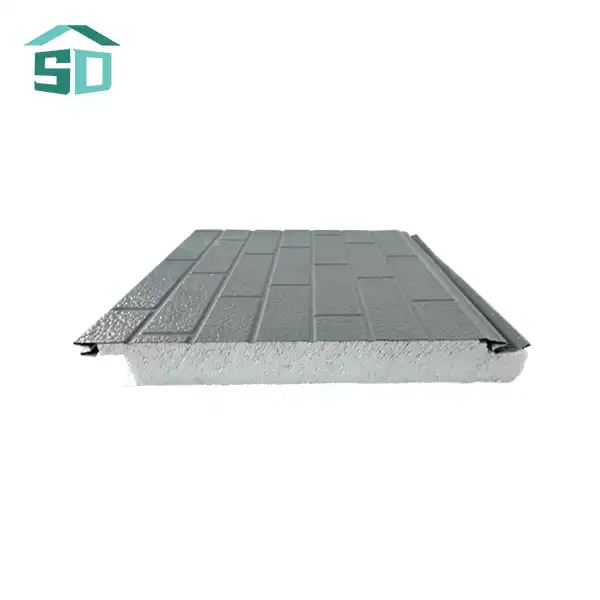

The exceptional durability of aluminum foam sandwich panels stems from their ingenious design and the properties of their constituent materials. At the heart of these panels lies a core of aluminum foam, a material that combines the strength of metal with the lightweight properties of foam. This core is sandwiched between two thin, yet strong, aluminum sheets, creating a composite structure that's greater than the sum of its parts.

Strength-to-Weight Ratio: A Game-Changer in Construction

One of the most striking features of aluminum foam sandwich panels is their impressive strength-to-weight ratio. Despite their lightweight nature, these panels boast a compressive strength of 52.7 kPa, making them capable of withstanding significant loads without deformation. This unique combination of strength and lightness allows architects and engineers to design structures that are both robust and energy-efficient, as less material is required to achieve the same structural integrity as traditional building materials.

Resistance to Environmental Factors

Aluminum foam sandwich panels exhibit remarkable resistance to various environmental factors that typically degrade building materials over time. With a waterproof rate of 0.0008, these panels effectively prevent moisture ingress, safeguarding the interior of buildings from water damage and mold growth. Moreover, their wind resistance of 8.0 kPa ensures that they can withstand high wind loads, making them suitable for use in areas prone to severe weather conditions.

Thermal Properties: Enhancing Longevity

The thermal properties of aluminum foam sandwich panels contribute significantly to their durability. With a thermal conductivity of 0.018 W/m.k and a thermal resistance of 2.09 m²K/W, these panels provide excellent insulation. This thermal efficiency not only enhances energy savings but also reduces thermal stress on the building structure, thereby extending its lifespan.

Applications Showcasing the Durability of Aluminum Foam Sandwich Panels

The durability of aluminum foam sandwich panels is evident in their wide range of applications across various sectors. From residential complexes to commercial buildings, these versatile panels have proven their worth in numerous construction projects.

Exterior Cladding: Weathering the Elements

As exterior cladding, aluminum foam sandwich panels face the harshest environmental conditions. Their corrosion resistance and weatherproof properties make them an ideal choice for building facades. Available in thicknesses of 16mm or 20mm for exterior applications, these panels provide a robust barrier against wind, rain, and UV radiation, maintaining their structural integrity and aesthetic appeal over extended periods.

Interior Wall Decorations: Combining Style and Substance

In interior applications, the 10mm thick aluminum foam sandwich panels offer a perfect blend of durability and design flexibility. Their customizable nature allows for a wide range of colors and patterns, enabling architects and designers to create visually striking interiors without compromising on structural integrity. The panels' fire-resistant properties, with a fire-protection rating of B1/B2, add an extra layer of safety to interior spaces.

Specialized Applications: Pushing the Boundaries of Durability

The exceptional durability of aluminum foam sandwich panels has led to their adoption in specialized applications where performance is paramount. In the renovation of historic buildings, these panels offer a lightweight yet sturdy solution that doesn't put undue stress on existing structures. Their use in security kiosks demonstrates their ability to provide both protection and aesthetic appeal in high-stakes environments.

Maintaining the Durability of Aluminum Foam Sandwich Panels

While aluminum foam sandwich panels are inherently durable, proper maintenance can further extend their lifespan and preserve their performance over time.

Regular Inspections: Preventing Minor Issues from Escalating

Periodic inspections of aluminum foam sandwich panels can help identify and address potential issues before they become serious problems. This includes checking for any signs of physical damage, ensuring that seals and joints remain intact, and verifying that the panels are securely fastened to the building structure.

Cleaning and Surface Care

Maintaining the cleanliness of aluminum foam sandwich panels not only preserves their aesthetic appeal but also contributes to their longevity. Regular cleaning with mild detergents and soft brushes can remove dirt and pollutants that might otherwise lead to surface degradation over time. For panels with specialized coatings, following manufacturer-recommended cleaning procedures is crucial to avoid damaging the protective layers.

Addressing Damage Promptly

In the rare event of damage to aluminum foam sandwich panels, prompt action is key to maintaining their durability. Small dents or scratches can often be repaired without compromising the panel's integrity. For more significant damage, consulting with the manufacturer or a qualified professional can help determine the best course of action, whether it's repair or replacement of the affected panel.

Conclusion

aluminum foam sandwich panels offer exceptional durability, making them a superior choice for both interior and exterior applications in construction. Their unique combination of strength, lightweight design, and resistance to environmental factors ensures long-lasting performance and aesthetic appeal. For those seeking to leverage the benefits of these innovative panels in their construction projects, Weifang Sandong Building Materials Co., Ltd. stands ready to provide expert guidance and high-quality products. To explore how aluminum foam sandwich panels can enhance your next project, contact us at info@sdqsc.com.