The Revolutionary Impact of Thermal Insulation Panels on Modern Construction

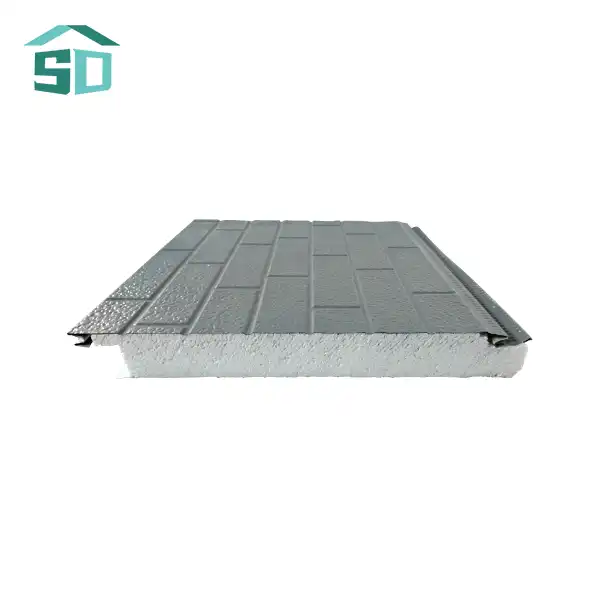

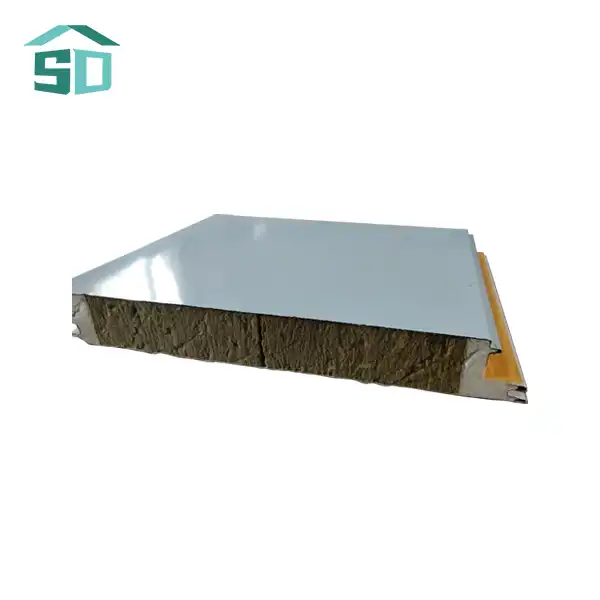

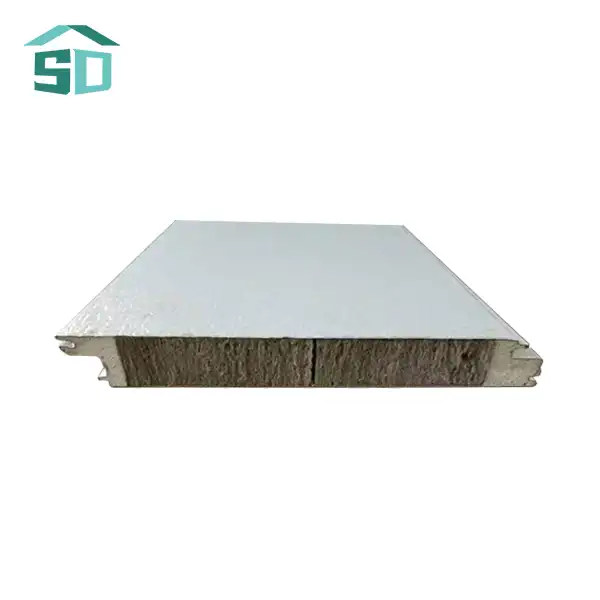

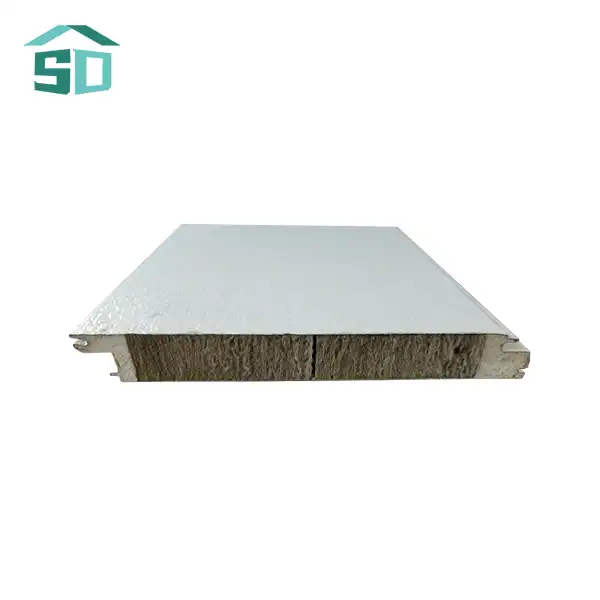

Warm separator boards have re-imagined the scene of present day development, advertising a large number of benefits that expand distant past insignificant cover. These boards are built to give a compelling boundary against warm and cold, guaranteeing year-round consolation for tenants whereas essentially decreasing vitality utilization. The predominant cover properties of these boards stem from their imaginative plan and high-quality materials.

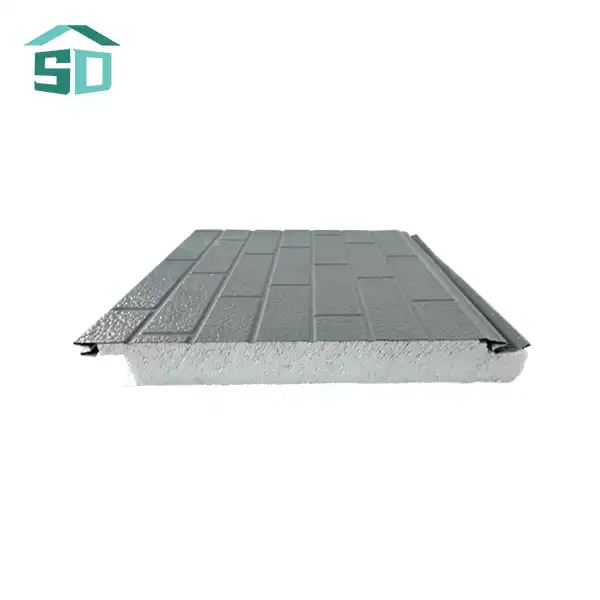

One of the standout highlights of warm separator boards is their unmatched solidness. Developed with strong materials, these boards are planned to withstand the test of time and cruel natural conditions. Their corrosion-free plan makes them impenetrable to corruption caused by dampness, UV beams, and other outside variables that regularly torment conventional building materials.

Safety is another crucial aspect where thermal insulation panels excel. With a fire-protection rating of B1/B2, these panels offer peace of mind to building owners and occupants alike. The non-flammable nature of the panels significantly reduces the risk of fire spread, contributing to overall building safety.

Versatility and Customization Options

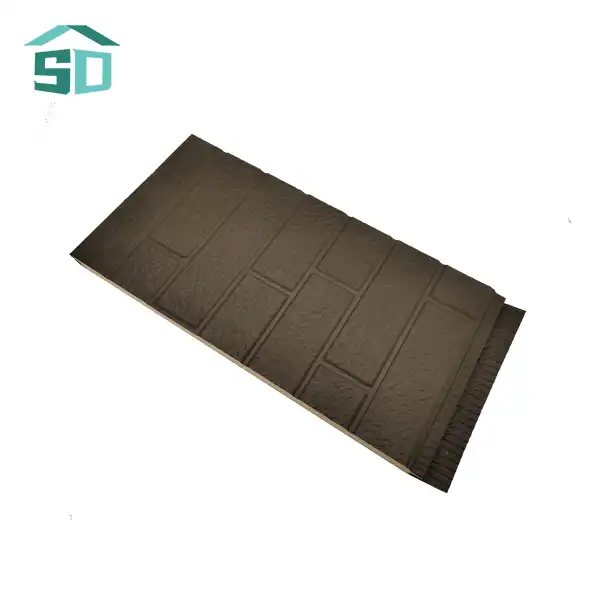

The flexibility of warm separator boards is genuinely exceptional. They can be utilized in a wide extend of development ventures, counting private complexes, workplaces, estates, gardens, noteworthy building remodels, civil buildings, and indeed security stands. This adaptability makes them a favorite among architects and builders who appreciate their superior performance and aesthetic appeal.

Moreover, these panels offer extensive customization options. Building owners can tailor the colors and patterns to suit any décor, ensuring that the panels not only perform well but also contribute to the overall aesthetic of the structure. This level of customization allows for seamless integration with various architectural styles and design preferences.

Technical Specifications and Performance Metrics

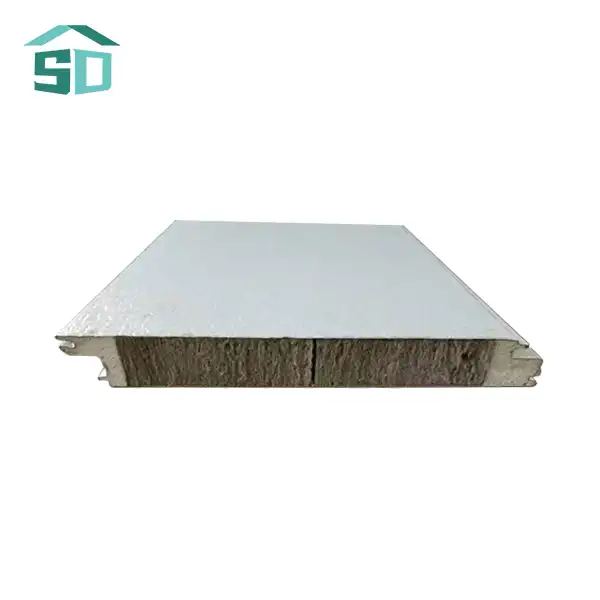

The technical specifications of thermal insulation panels further underscore their quality and effectiveness. With a thermal conductivity of 0.018W/m.k and a thermal resistance of 2.09m2k/w, these panels provide exceptional insulation properties. The panels boast an impressive waterproof rate of 0.0008 and can withstand wind resistance up to 8.0 Kpa, ensuring robust protection against the elements.

Available in various dimensions to suit different applications, the panels come in thicknesses ranging from 10mm for interior use to 16mm/20mm for exterior applications. The width options include 383mm for exterior panels and 450mm for interior panels, providing flexibility in installation and design.

Cost-Effective Solutions Without Compromising on Quality

One of the most compelling aspects of thermal insulation panels is their ability to offer high-performance insulation at a competitive price point. This cost-effectiveness does not come at the expense of quality; rather, it is a result of innovative manufacturing processes and efficient material usage.

The long-term cost savings associated with thermal insulation panels are significant. By providing superior insulation, these panels dramatically reduce heating and cooling costs, leading to substantial energy savings over the lifetime of the building. This reduction in energy consumption not only benefits the building owner's bottom line but also contributes to a smaller carbon footprint, aligning with green building initiatives.

Eco-Friendly and Sustainable

Speaking of green building, thermal insulation panels are at the forefront of sustainable construction practices. Manufactured using eco-friendly materials and processes, these panels contribute to reducing the overall environmental impact of construction projects. Their durability and long lifespan also mean less frequent replacements, further minimizing waste and resource consumption.

The energy efficiency provided by these panels also plays a crucial role in reducing a building's carbon emissions. By minimizing the need for artificial heating and cooling, thermal insulation panels help create more sustainable and environmentally responsible structures.

Simplified Installation Process

Another factor contributing to the cost-effectiveness of thermal insulation panels is their simplified installation process. The ease of installation not only reduces labor costs but also speeds up construction timelines, leading to faster project completion and reduced overall project costs.

The installation process typically involves the following steps:

1.Preparation: Ensuring the surface is clean, dry, and free of debris.

2.Layout: Planning the panel arrangement according to design specifications.

3.Cutting: Trimming panels to required sizes using suitable cutting tools.

4.Attachment: Securing panels using mechanical fasteners or adhesive as per project requirements.

5.Sealing: Applying sealant around edges to prevent moisture ingress and ensure a tight fit.

While the installation process is straightforward, it's recommended to consult with professionals to ensure optimal results and maximize the benefits of these high-performance panels.

Quality Assurance and Manufacturing Excellence

The superior quality of thermal insulation panels is a result of rigorous manufacturing processes and stringent quality control measures. Leading manufacturers in the industry, such as Weifang Sandong Building Materials Co., Ltd., employ state-of-the-art production lines and comprehensive quality control systems to ensure every panel meets the highest standards of performance and durability.

The quality confirmation prepare starts with the cautious choice and testing of crude materials. Steel coils, aluminum thwart, and polyurethane experience strict testing to guarantee they meet the required details. All through the fabricating handle, comprehensive assessments are carried out to confirm item thickness, paint film thickness, mechanical quality, fire retardancy, and in general appearance.

Continuous Innovation and Improvement

The warm separator board industry is characterized by nonstop development and advancement. Producers contribute intensely in investigate and improvement to upgrade board execution, investigate modern materials, and create more effective generation methods. This commitment to advancement guarantees that warm separator boards proceed to advance, advertising indeed more noteworthy benefits to the development industry and end-users.

Recent advancements have focused on improving the panels' thermal properties, increasing their fire resistance, and enhancing their overall durability. These ongoing improvements ensure that thermal insulation panels remain at the forefront of building technology, providing ever-increasing value to construction projects.

Global Recognition and Industry Standards

The quality and execution of warm separator boards have picked up acknowledgment around the world. These boards meet or surpass different universal measures and building codes, making them a dependable choice for ventures over the globe. Their compliance with rigid industry benchmarks gives confirmation to planners, builders, and building proprietors that they are contributing in a item that conveys on its guarantees.

As the construction industry continues to prioritize energy efficiency and sustainable building practices, the demand for high-quality thermal insulation panels is expected to grow. Their ability to combine affordability with superior performance positions them as a key component in the future of construction.

Conclusion

Thermal insulation panels represent a significant leap forward in building technology, offering an unparalleled combination of affordability, quality, and performance. Their ability to provide superior insulation, durability, and aesthetic versatility makes them an invaluable asset in modern construction projects. As we continue to strive for more energy-efficient and sustainable buildings, thermal insulation panels will undoubtedly play a crucial role in shaping the future of architecture and construction.

For those looking to elevate their next construction project with high-quality, affordable thermal insulation panels, Weifang Sandong Building Materials Co., Ltd. stands ready to provide expert guidance and superior products. To learn more about our extensive range of exterior cladding and facade solutions, including our state-of-the-art thermal insulation panels, don't hesitate to reach out to us at info@sdqsc.com.