- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Acoustic Aluminum Foam Panels for Noise Reduction

In the realm of modern construction and acoustics, aluminum foam sandwich panels have emerged as a game-changing solution for noise reduction. These innovative panels combine the lightweight strength of aluminum with the sound-absorbing properties of foam, creating a versatile material that’s revolutionizing how we approach noise control in various settings. From bustling office spaces to high-speed trains, these panels are setting new standards in acoustic performance and energy efficiency. Partnering with a trusted aluminum foam sandwich panel supplier ensures access to precision-engineered products that meet stringent industry standards, offering enhanced sound insulation, fire resistance, and long-term durability for both architectural and industrial applications.

Inroducing Aluminum Foam Sandwich Panels

What Are Aluminum Foam Sandwich Panels?

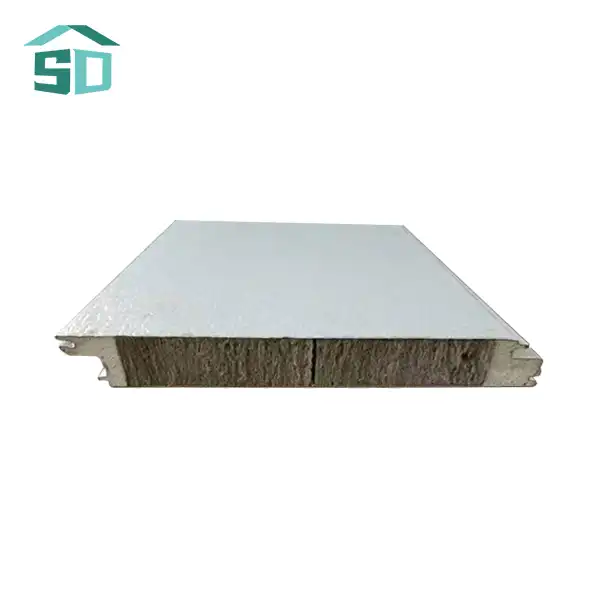

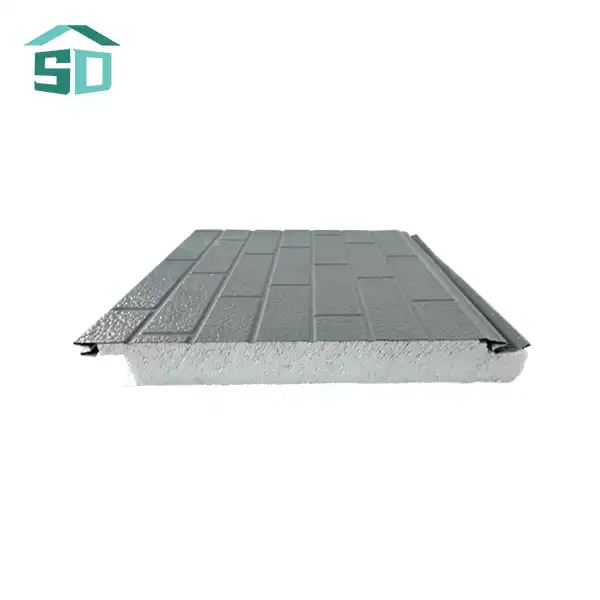

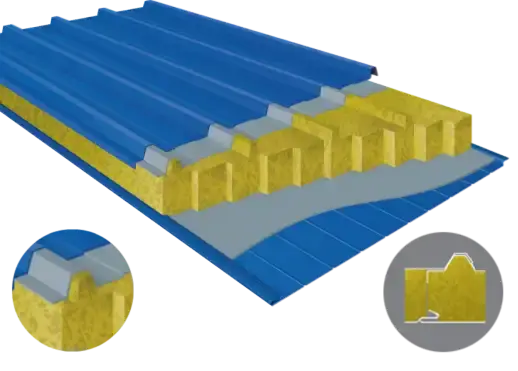

Aluminum foam sandwich panels are advanced composite materials consisting of two dense aluminum face sheets bonded to a lightweight aluminum foam core. This unique structure results in a panel that boasts exceptional strength-to-weight ratio and impressive sound absorption capabilities. The aluminum foam core, with its intricate network of interconnected pores, acts as a highly effective sound dampener, trapping and dissipating acoustic energy. This porous structure not only reduces noise transmission but also enhances vibration absorption, making it ideal for environments requiring both quiet operation and structural stability.

The Manufacturing Process

The production of aluminum foam sandwich panels involves a sophisticated process that combines metallurgy and materials science. Aluminum alloy powders are mixed with foaming agents and compressed into a precursor. This precursor is then heated to its melting point, causing the foaming agent to release gas, which creates the characteristic porous structure. The foam is then sandwiched between solid aluminum sheets and bonded to create the final panel.

Key Properties of Aluminum Foam Sandwich Panels

Aluminum foam sandwich panels offer a unique combination of properties that make them ideal for acoustic applications:

- High strength-to-weight ratio

- Excellent sound absorption

- Low thermal conductivity

- Fire resistance

- Corrosion resistance

- Impact energy absorption

These properties make aluminum foam sandwich panels a versatile solution for various industries, from construction to transportation.

Acoustic Performance of Aluminum Foam Panels

Sound Absorption Mechanism

The acoustic performance of aluminum foam sandwich panels stems from their unique structure. As sound waves enter the porous foam core, they are scattered and reflected within the complex network of cells. This process converts sound energy into heat through friction and viscous effects, effectively reducing the intensity of the reflected sound. The result is a significant reduction in noise levels across a wide frequency range.

Noise Reduction Coefficient (NRC)

The effectiveness of aluminum foam sandwich panels in reducing noise is often measured by their Noise Reduction Coefficient (NRC). This value represents the average sound absorption across different frequencies, with higher values indicating better performance. Aluminum foam panels typically achieve NRC ratings between 0.6 and 0.9, making them highly effective for noise control applications.

Comparison with Traditional Materials

When compared to traditional acoustic materials like fiberglass or mineral wool, aluminum foam sandwich panels offer several advantages:

- Higher durability and longevity

- Better fire resistance

- Easier maintenance and cleaning

- Improved structural integrity

- Potential for decorative finishes

These benefits make aluminum foam sandwich panels an attractive option for architects and designers looking to combine acoustic performance with aesthetic appeal and long-term durability.

Applications of Acoustic Aluminum Foam Panels

Transportation Industry

The transportation sector has embraced aluminum foam sandwich panels for their ability to reduce noise while maintaining structural integrity. These panels find applications in:

- High-speed train carriages

- Aircraft cabins

- Automotive interiors

- Marine vessels

By incorporating aluminum foam sandwich panels, vehicle manufacturers can create quieter, more comfortable environments for passengers while also benefiting from the material's lightweight properties, which contribute to improved fuel efficiency.

Building and Construction

In the construction industry, aluminum foam sandwich panels are increasingly used for both interior and exterior applications:

- Sound barriers along highways and railways

- Acoustic treatments for concert halls and auditoriums

- Noise reduction in office spaces and meeting rooms

- Soundproofing for residential buildings

The versatility of aluminum foam sandwich panels allows architects to address acoustic challenges while also meeting aesthetic and structural requirements.

Industrial Noise Control

Manufacturing facilities and industrial environments often struggle with high noise levels. Aluminum foam sandwich panels offer an effective solution for:

- Enclosures for noisy machinery

- Acoustic baffles in large industrial spaces

- Soundproofing of generator rooms and HVAC systems

- Noise reduction in testing facilities

By implementing these panels, companies can create safer, more comfortable work environments while also complying with occupational noise regulations.

Conclusion

Aluminum foam sandwich panels represent a significant advancement in acoustic technology, offering a unique combination of sound absorption, structural integrity, and design flexibility. Their ability to effectively reduce noise across various applications makes them an invaluable tool in our increasingly noisy world. As we continue to seek innovative solutions for noise control, aluminum foam sandwich panels stand out as a versatile and high-performance option that meets the demands of modern construction and design.

At Weifang Sandong Building Materials Co., Ltd., we're committed to providing cutting-edge exterior cladding solutions, including advanced aluminum foam sandwich panels. Our products offer unparalleled acoustic performance, thermal insulation, and aesthetic versatility. Whether you're working on a high-rise office building, a residential complex, or a transportation project, our expert team can help you find the perfect acoustic solution. Ready to enhance your project with state-of-the-art noise reduction technology? Contact us today at info@sdqsc.com to explore how our aluminum foam sandwich panels can transform your space.

FAQ

How do aluminum foam sandwich panels compare to traditional insulation materials?

Aluminum foam sandwich panels offer superior durability, fire resistance, and structural integrity compared to traditional materials, while maintaining excellent acoustic properties.

Are aluminum foam sandwich panels suitable for outdoor use?

Yes, these panels are corrosion-resistant and can withstand various weather conditions, making them ideal for outdoor applications such as sound barriers.

Can aluminum foam sandwich panels be customized for specific projects?

Absolutely. Manufacturers can tailor the thickness, density, and surface finishes of the panels to meet specific project requirements and aesthetic preferences.

References

1. Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

2. Ashby, M. F., Evans, A., Fleck, N. A., Gibson, L. J., Hutchinson, J. W., & Wadley, H. N. G. (2000). Metal Foams: A Design Guide. Butterworth-Heinemann.

3. Lu, T. J., Hess, A., & Ashby, M. F. (1999). Sound absorption in metallic foams. Journal of Applied Physics, 85(11), 7528-7539.

4. Baumeister, J., Banhart, J., & Weber, M. (1997). Aluminium foams for transport industry. Materials & Design, 18(4-6), 217-220.

5. García-Moreno, F. (2016). Commercial Applications of Metal Foams: Their Properties and Production. Materials, 9(2), 85.